Bridges are marvels of architectural engineering that stand peacefully among us. We don’t think of them much, even when we are passing over them. But when you take a moment to realize the problems these infrastructures solve, you begin to appreciate the importance and rich history behind them.

By definition, a bridge is a structure built to span a physical obstacle, such as a body of water, valley, or road. It is constructed for the purpose of providing passage over the obstacle, something that is otherwise difficult or impossible to cross.

When we look back in time, it is likely that some of the earliest bridges in history were trees that had fallen over a body of water providing passage. When it comes to man-made construction, the arched Arkadiko Bridge which dates to around 1300 - 1190 BCE, in Southern Greece, is thought to be one of the oldest bridges on the planet that is still in use. In its earlier days, the Arkadiko bridge served as a highway between the cities of Tiryns and Epidaurus.

Yes, the engineering of bridges has changed quite a bit since horse-drawn chariots roamed the cobblestone streets of the Greek Bronze Age. Today, bridge construction now encompasses seven different types of designs, and these architectural sensations continue to improve year after year. So, what are these types of bridges? Let’s find out.

Types of Bridges:

- Truss

- Cantilever

- Cable-stayed

- Suspension

- Arch

- Beam

- Tied-arch

Beautiful view of the magnificent Astoria Megler Bridge crossing the Columbia River from Astoria, Oregon to Washington. Photo courtesy of iStock/DC_Colombia

Truss Bridges:

Truss bridges are the most popular design among all the others due to their lower requirements for construction materials. The most common building materials found in Truss bridges are timber, iron, steel, and concrete. The design incorporates a diagonal mesh of triangle-shaped posts above the bridge to distribute forces of tension across the entire structure. Truss bridges are built to withstand heavier weight than other bridges and are often seen in higher freight-traveled areas.

Located 196 feet above the Columbia River in, Astoria, Oregon. The truss-designed Astoria-Megler Bridge stretches 4.067 miles with a width of 28 feet. This two-lane bridge is only accessible by motor vehicles and bicycles, no foot traffic is allowed.

Duluth lift bridge in Minnesota on Lake Superior. Photo courtesy of iStock/jimkruger

Duluth lift bridge in Minnesota on Lake Superior. Photo courtesy of iStock/jimkruger

Cantilever Bridges:

Cantilever bridges are usually located over water and designed with three spans of which the outer two anchors at the shoreline and cantilever out over the waterway. The central span rests on the arms extending from the outer spans. These bridges distribute the forces of tension through the lower cords, and compression through the upper cords. Larger Cantilever bridges are primarily used for rail traffic.

Easily one of the most interesting cantilever bridge designs in the country. The Aerial Lift Bridge in Duluth, Minnesota is a sight to be seen. Serving freight transportation both for land and sea, this bridge is used primarily for railway transport. So, why is the word “Aerial” in a bridge's name being that they are anchored into the ground? Here comes the interesting part. This bridge uses a cable system to rise 135 feet in the air allowing freight ships cruising the ice-cold waters of Lake Superior to pass under. To get the bridge to lift, ship captains must use a “Long-short-short” horn blow to request the bridge's accent.

Estaiada Bridge Octavio Frias de Oliveira in Sao Paulo, Brazil. Photo courtesy of iStock/R.M. Nunes

Estaiada Bridge Octavio Frias de Oliveira in Sao Paulo, Brazil. Photo courtesy of iStock/R.M. Nunes

Cable-stayed Bridges:

Cable-stayed bridges are the youngest sibling of the bunch. This design is by far the fastest developing and most promising bridge system looking into the future. The weight of the deck is supported by several nearly straight diagonal cables in tension running directly to one or more vertical towers. The towers transfer the cable tension forces to the foundations through vertical compression. The most common building materials used include concrete towers, steel rope, and concrete box girders. These bridges are popular for carrying public traffic over a medium or long distance but can also support almost all forms of transportation, except heavy rail.

South of the equator in São Paulo, Brazil. The Octávio Frias de Oliveira Bridge is the only bridge in the world that has two curved tracks supported by a single concrete mast. Its unusual “X” shaped deck draws in the eyes of anyone passing by. At the end of December each year, lights are put up on the cables and illuminated to create the color effects of a Christmas Tree.

San Francisco Bay area in California. Photo courtesy of iStock/Don White

San Francisco Bay area in California. Photo courtesy of iStock/Don White

Suspension Bridges:

Suspension bridges are probably the most recognizable of all bridges in the U.S. and are self-explanatory. They are stabilized with vertical towers and connected by long swooping suspension cables anchored from land to tower, to the tower, and back to land again. Smaller vertical suspenders distribute the force of tension to the bridge deck, and this is what holds the bridge up. Suspension bridges are typically used for pedestrian traffic and trucking freight.

As you read this, I am sure the world’s most iconic suspension bridge has already come to mind, the Golden Gate Bridge in San Francisco, CA. Completed in 1937, the Golden Gate Bridge is the most popular bridge in the U.S. drawing over 10 million visitors to the bay area each year.

Bixby Bridge and Pacific Coast Highway at sunset. Photo courtesy of iStock/miroslav_1

Bixby Bridge and Pacific Coast Highway at sunset. Photo courtesy of iStock/miroslav_1

Arch Bridges:

Arch bridges are one of the oldest types of bridges known to man. An arch bridge works by sending the force of tension from the top of the keystone, down through the voussoirs (wedge-shaped or tapered stone), then to the footers. The inward force of the abutments keeps the tension moving further into the ground. Arch bridges have a wide range of uses. They can be used for walking, biking, cars, trucks, and trains, the possibilities are endless with this timeless design.

Sitting along the coast of Big Sur is the California staple Bixby Creek Bridge. This arched bridge is as scenic as the mountainous Pacific coastline that it looks over. Bixby’s rainbow-like design draws in over 8 million visitors per year and is truly a sight to behold.

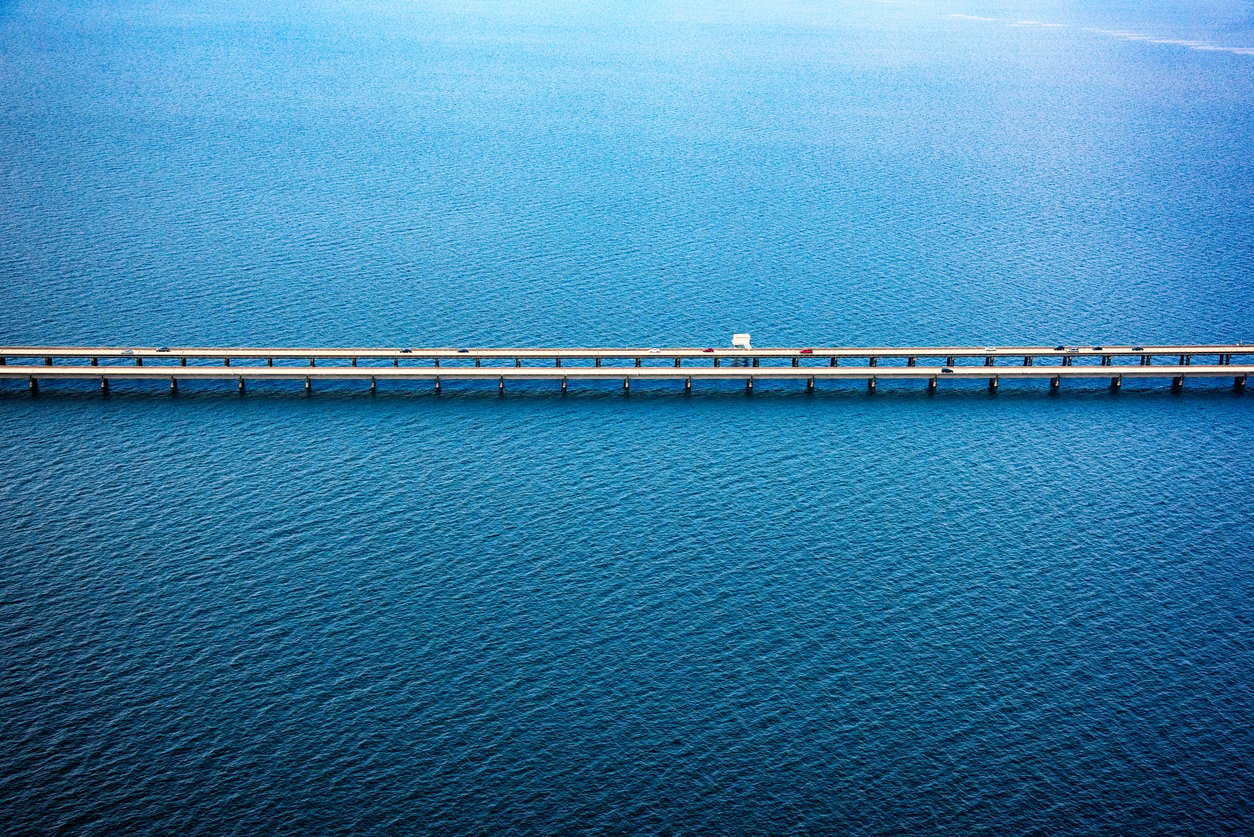

Lake Pontchartrain Causeway. Photo courtesy of iStock/Art Wager

Lake Pontchartrain Causeway. Photo courtesy of iStock/Art Wager

Beam Bridges:

Beam bridges are by far the simplest and cheapest of the group. With a wide deck, the force of compression from the weight above pushes the load inward and into the pillars in the middle of the bridge that carries the load.

The longest beam bridge over water in the world is in Louisiana. It is called the Lake Pontchartrain Causeway stretching 24 total miles connecting New Orleans, LA to Mandeville, LA. Since 1956, this passage has been providing commuter and freight traffic a simpler route in and out of the New Orleans city limits.

Puente de Las Américas one of the three bridges that pass over the Panama Canal. Photo courtesy of iStock/Faustino Sanchez

Puente de Las Américas one of the three bridges that pass over the Panama Canal. Photo courtesy of iStock/Faustino Sanchez

Tied-arch:

Tied-arch bridges are also referred to as bowstring bridges since they look like a bow from the side profile. This design uses horizontal thrust from both sides to support an arched structure, just like a regular arch bridge. But instead of an arch supporting the structure from below, the arch rises above the road, and vertical ties descend to increase the support of the deck. Theoretically, the design and distribution of tension are flipped upside down, in comparison to arch bridges.

At the Pacific entrance of the Panama Canal is the Bridge of the Americas. This cantilever-designed tied-arch bridge provides passage over the busiest shipping canal in the entire world. Opening in 1962, this bridge is not for the faint of heart. Sitting 384 feet above the water, it will surely give you a kick of adrenaline as you pass over.

Brooklyn Bridge from East River sunset with flare. Photo courtesy of iStock/NicolasMcComber

Brooklyn Bridge from East River sunset with flare. Photo courtesy of iStock/NicolasMcComber

Americas Bridges:

America’s bridges are not only masterpieces showcasing our nation’s civil engineering, but they are also magnificent forms of architectural art. Since the 1800s many bridges have become American icons including the Brooklyn Bridge, Golden Gate Bridge, Seven Mile Bridge, and the Chesapeake Bay Bridge-Tunnel.

The older of America's two most iconic suspension bridges is the Brooklyn Bridge in New York City. Since opening in 1883, the Brooklyn Bridge has provided passage for pedestrians from Brooklyn to the southern tip of Manhattan. According to the Department of Transportation, more than 100,000 cars, 4,000 cyclists, and 10,000 walkers cross the bridge each day. The bridge spans 1,595 feet and sits 276.5 feet above the East River offering breathtaking views of Manhattan’s picturesque skyline.

The younger of the two iconic suspension bridges is, you guessed it, the Golden Gate Bridge in San Francisco, CA. Since 1937, the world-famous Art Deco styling and orange color has caught the eye of millions, and quite possibly billions of tourists. Each year, over 10 million people visit this bridge to gaze at the 746-foot-tall masterpiece. Just northwest of the bridge at the Marin Headlands, you can look down on the Golden Gates as well as the cityscape of San Francisco. It is a breathtaking sight.

Transitioning 3,207 miles southeast from San Francisco, CA to the southern tip of Florida in the Keys lies the beam-style bridge built, over water, the Seven Mile Bridge. The distance of the bridge lies directly in the name. This east coast icon connects Knight’s Key in the Middle Keys to Little Duck Key in the Lower Keys (so many keys). This bridge is used primarily for car traveling tourists and adventure cyclists. Standing only 65 feet above the ocean’s surface with a width of 38 feet, this scenic bridge has long been one of the most desirable drives that our country has to offer.

So, the best has been saved for last. What might this bridge be? Surprise! The Chesapeake Bay Bridge-Tunnel. Located only 198 miles south of The Dixon Group’s Chestertown, MD headquarters is an engineering wonder. Crossing over and under open waters where the Chesapeake Bay meets the Atlantic Ocean, the Bridge-Tunnel provides passage between Norfolk, Virginia, and Virginia’s Eastern Shore. When it was opened in April of 1964, the bridge was selected as “One of the Seven Engineering Wonders of the Modern World”. The bridge measures 17.6 miles including two one-mile underwater tunnels. There are also some interesting facts about this famous bridge.

The Facts:

- It has four manmade islands each with approximately 5.25 acres of surface 30 feet above sea level.

- Two underwater tunnels allow freight and cruise ships easy passage to enter and exit the highly traveled Chesapeake Bay.

- It only took 3.5 years to build the original 2-lane bridge-tunnel

- The original 2-lane bridge-tunnel was opened in April 1964, and it cost $200 million ($1.7 billion in 2021 with inflation calculated) for planning, design, right-of-way, and construction

- New parallel 2-lane trestles have been built and they were completed in April 1999, at a cost of $197 million ($313 million in 2021 with inflation calculated in)

- No local, state, or federal tax money was used for this project

- The bridge-tunnel is supported financially by the tolls collected from the motorists who use the structure

Construction of the Queensferry Crossing over the Firth of Forth. Photo courtesy of iStock/georgeclerk

Construction of the Queensferry Crossing over the Firth of Forth. Photo courtesy of iStock/georgeclerk

How It Is Built:

With so many types of bridges, the construction process varies. Building a bridge is a long and tedious project that can take years to complete depending on the size and other factors. Before construction planners must go out and test items such as the strength of the soil, the depth needed, and even the layout of the land that is being built on. In today’s age, technology plays a major part in this process as well. Engineers use software programs to design and test the behavior of the bridge in different weights and weather conditions to better understand their limits. After the planning is complete, designs are approved, and all necessary requirements are met, contractors can begin construction and break ground.

At the beginning of the construction stages for a suspension bridge, most of the time and labor is spent assembling structures that help maintain and support the foundation. There are two towers on each end of the bridge. These towers are formed by sinking caissons into the water, then hammering them down into the ground below. Once these are set, the water in the caissons must be pumped out. The concrete is then poured, and the towers are formed.

The next step in the process is critical, being that it is the most important part of the bridge. This part is the installation of the cables. These cables stretch across the deck and hold the bridge in position. From tower to tower, the weight of these massive cables tries to pull the towers in towards each other. Therefore, the cables must be anchored into the ground to prevent that from happening. The cables are installed and anchored on one end of the bridge, ran up through the tower, then stretched across the deck to the tower on the opposite end, and anchored into the ground again.

Once the cables are completed, the hangers that connect the cables to the deck are installed. These hangers are what support the load of the bridge. They dangle vertically between the towers across the middle of the bridge and swoop under the deck providing support to the structure above. This leads to the final step of the construction process, the bridge deck. The deck is tied in and suspended by the hangers to support the roadway above.

So, in review of the building process. The towers are the primary foundation for the bridge. The towers support the cables that stretch from one end of the bridge to the other, the cables support the hangers that wrap under the deck of the bridge providing support to the weight of the loads passing above.

Construction Equipment and Tools:

Bridge construction today looks much different than it did in the 13th Century BC. With newer equipment, technology, and engineering, today’s bridges are not only constructed faster but better. When constructing a bridge, a wide variety of equipment and tools are needed to get the project done.

Some of the Equipment and Tools Needed Include:

- Aerial lifts

- Vertical masts

- Drones

- Telehandlers

- Excavators

- Skid loaders

- Backhoes

- Cranes

- Air compressors

- Concrete saws

- Light towers

There is always an added risk when it comes to construction in the bridge-building process. Some of these challenges include elevated working spaces, heavy equipment, and even mother nature. To help prevent injury or death, manufacturers have worked tirelessly to develop tools and techniques to reduce risk.

Over the years, Dixon’s team of engineers has developed a diverse line of outside air safety products to help keep you and your workforce safe.

Dixon’s Outside Air Products in Bridge Construction:

Dixon manufactures and supplies solutions for many of the challenges experienced in construction sectors including bridges. Outside air products are a vital and important component of many bridge construction sites. We offer a complete line of air hose fittings and accessories to ensure that your site remains OSHA compliant: whether it is air couplings, in-line lubricators, fittings, or clamps. Dixon products have stood the test of time and are readily available.

2-Lug Male NPT End

2-Lug Male NPT End

2-Lug Triple Connection

2-Lug Hose End

Dixon Air King™:

Dixon’s Air King couplings are recommended for use on air lines for virtually any type of pneumatic equipment. Air King fittings feature a universal head design that couple together with a simple quarter turn regardless of hose or adapter size making them fast and easy to use. Sizes 3/8” up to 1” have two lugs, while sizes 1-1/4” through 2” have four lugs. To couple them, press two couplers together and turn ninety degrees. Air King couplings are offered in iron, brass, and 316 stainless steel. Couplings are rated up to 150 PSI at 70 degrees Fahrenheit (21°C).

There are three safety features built into every Air King:

- Washer Design: Dixon AWR4 washers, supplied with every Air King, are designed to seal up to 150 PSI. The washer design helps keep the coupling together when pressurized by expanding and pushing against coupler halves.

- Internal Lug Design: Cast inside each Air King lug is a ninety-degree step that locks with an opposite step on the outside of the adjoining Air King part. These step-locks provide additional holding power to keep the Air King connected up to its 150 PSI rating at 70°F (21°C) ambient temperature.

- Safety Clip: Unexpected twisting of hose assemblies can occur during use. To eliminate the possibility of an accidental disconnect, each Air King comes with a safety clip. This clip is designed to be inserted into the locking holes on the fittings. Being able to insert the safety clip also assures the user that the fittings have been properly connected.

In-Line Lubricators:

We shouldn’t forget the In-Line lubricator or “football oiler”. This is a rugged lubricator designed to withstand the abuse found in a harsh outdoor work environment. All air tools need oil to keep them running properly. Dixon’s inline lubricators protect portable or stationary air tools by efficiently oiling the tool mechanisms, each time an air tool is operated a fine mist of oil is injected into it along with the air from the compressor. The inline lubricator has two reservoirs. The upper reservoir holds the oil and a lower reservoir that is the passageway for the air to enter. The air and oil mixture exit through the lower reservoir. The oil adjustment valve between the two compartments initially allows air to enter the reservoir to pressurize it, and then it controls the amount of oil entering the air stream. In conclusion, tool rebuilds are expensive, inline lubricators save money by helping cut down on them.

Dual-Lock P-Series Thor Interchange Female Thread Coupler

Dual-Lock P-Series Thor Interchange Female Thread Coupler

Dual-Lock P-Series Thor Interchange Female Thread Plug

Dual-Lock P-Series Thor Interchange Female Thread Plug

Dixon Dual-Lock Pneumatic Couplers:

Dixon Dual-Lock pneumatic couplers are also used in the construction of bridges. They are designed for use in air and nitrogen applications with working pressure up to 300 PSI and operating temperatures of between -40 and 250 degrees Fahrenheit. The Unisex design means that any Dual-Lock coupler of the same size will couple with another. The spring-loaded interlocking engagement of the coupler requires nothing more than pushing the couplers together and twisting.

Why Choose the Dixon Dual-Lock Coupler?

- Heavy-duty construction, Made in the USA means longer lasting and maximized performance.

- The unisex design means fewer inventory items to track and match.

- Ease of connecting and disconnecting increases operational efficiencies.

- Spring-loaded interlocks and safety keys ensure against accidental disconnection.

Connecting pressurized air with Dixon Dual-Lock couplings results in less wasted time, increased profitability, and greater peace of mind in knowing that you are using the best product on the market.

Overall:

Over the decades, bridges have become masterpieces of modern-day engineering. Even with the research and development of safer building processes, it is always best to stay updated, educated, and aware of the best safety tools on the market to better protect your workforce.

Please visit our Outside Air market page to learn more about additional Dixon products used in the construction of bridges. Also, If you would like to speak with a Dixon Specialist, please call 877.963.4966 or visit our website at dixonvalve.com.

If you enjoyed this read, please share it with your colleagues!