The shift towards renewable energy sources like solar and wind is inevitable to meet growing electricity needs, yet for the present, our society remains reliant on oil and gas to fuel our daily lives. With U.S. natural gas production projected to rise by 15% through 2050, much of this demand stems from increased export needs. Consequently, the oil and gas industry continues to depend on hydraulic fracturing, or fracking, a process demanding resilient equipment to endure its harsh environment.

Hydraulic Fracturing in a Nutshell

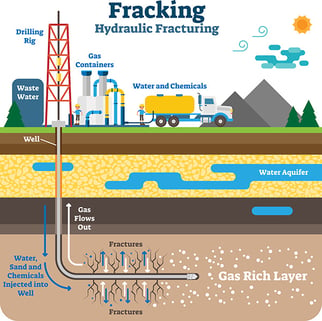

To start the process of hydraulic fracturing, a well is drilled up to 20,000 feet into the Earth. Then, a slurry composed of pressurized water, sand, and chemicals is sent through the well to create small fissures in the bedrock formations. The cracking exposes the oil or gas reserves for extraction.

Fracking's demanding nature subjects equipment to considerable wear and tear. Factors such as temperature, pressure, vibration, and the abrasive slurry composition decrease the lifespan of fracking equipment and components.

Choosing the Right Valve

There are two sides of hydraulic fracturing: High-Pressure Systems (HPS) and Low-Pressure Systems (LPS). Both systems require industrial valves for operation. Matching the valve type with the system's requirements is crucial. For example, HPS favor ball and gate valves for their resilience to sand slurry, while LPS benefit from butterfly valves.

Butterfly valves are used on blenders, which is the equipment where the slurry is prepared, and the low-pressure sides of missiles and pressure pumpers. The valves fit between two flanges and are simple to operate and replace.

Proper Butterfly Valve Maintenance

Although butterfly valves have a finite lifespan in the demanding fracking environment, regular maintenance will go a long way in extending the life of the equipment. This is done by greasing the valves monthly and flushing them after they’ve been exposed to harsh chemicals to encourage longevity.

Even with preventative maintenance, replacing the valves is unavoidable. However, simple replacement procedures facilitate swift repairs to minimize operational downtime.

Dixon’s Heavy-Duty Butterfly Valve

The Boss® LPS butterfly valve aims to address the unique challenges of fracking operations. The valve was designed for low-pressure hydraulic fracturing applications to assist with the transfer of water, acids, chemicals, slurries, and other liquids.

The valve disc, which is the part responsible for opening and closing the valve, is made out of a robust ductile iron suited to withstand the harsh fracking environment. Stainless steel, Halar coated, or carburized options are also available depending on the application. The valve shafts are made of stainless steel, which tolerates extreme conditions to keep the valve functioning as long as possible.

The butterfly valves feature a thick stem and a grease zerk added to the body neck to deliver a more durable and reliable performance. The valves are available in 2", 3", 4", 5", 6", and 8" sizes and have a maximum working pressure of 50 PSI to 200 PSI at -20°F (-29°C) to 200ºF (93°C) depending on the size and materials. View the full specifications here.

Additionally, Dixon provides actuation for industrial and sanitary valves. Remote actuation of butterfly valves enhances safety by removing personnel from high-pressure zones. Electric and pneumatic actuators are available for this purpose.

Summary

Dixon understands the importance of the oil and gas industry. Through innovation and expertise, Dixon is committed to improving productivity and reducing environmental and safety-related incidents on the low-pressure side of hydraulic fracturing sites. The cornerstone products are built around the premise of no welds, no threads, no leaks.

With 12 U.S. distribution centers stocked and ready to ship, we take pride in ensuring you always have The Right Connection®. For more information or recommendations on your specific application, visit dixonvalve.com or call 877.963.4966.