Slurry transport is essential for mining operations, moving mixtures of water and solid particles through pipelines. Valves play a critical role in keeping this process reliable and efficient. Choosing the right slurry line valve isn’t just about performance, it’s about preventing unplanned downtime, extending equipment life, and keeping operations safe and cost-effective.

What are Some Challenges of Slurry Applications?

Slurry service is notoriously tough on valves because of the unique characteristics of the mixture. High solid content accelerates wear on internal components, while uneven particle sizes can erode sealing surfaces. Slurries also tend to settle, which can cause buildup, clogging, or even complete blockages inside valve cavities. In some cases, chemical composition adds another layer of corrosion risk.

What Factors Should be Considered When Selecting a Slurry Valve?

There are several key factors to keep in mind when selecting a valve for mining operations. Take note of the particle size and hardness of the slurry to determine valve compatibility. Also consider the temperature of the slurry and the surrounding environment to ensure the selected valve can withstand the exposure. Pressure is another critical factor. The maximum system pressure should be determined by the lowest-rated component. Lastly, consider maintenance requirements to factor in how easy the valve is to repair or even replace if necessary.

What Types of Valves are Common for Slurry in Mining?

Knife gate valves, pinch valves, ball valves, and diaphragm valves are all common slurry line valves in mining operations.

Knife Gate Valves

Knife gate valves use a sharpened disc (the “knife”) that slides down to cut through the media and stop flow. When open, the gate lifts to allow slurry to pass through. These valves work well for on/off service but are not ideal for throttling or control due to wear and potential leakage.

Pinch Valves

Pinch valves use a flexible rubber sleeve that is compressed or “pinched” closed to stop flow. In mining applications, only the sleeve contacts the slurry which protects the valve body from abrasion.

Ball Valves

Ball valves are another industrial valve used in slurry applications. These valves feature a rotating ball with a hole through the center. When aligned with the pipeline, slurry flows. When turned, the ball blocks the flow. Ball valves are compact, offer quick operation with a quarter turn, and provide tight shutoff.

Diaphragm Valves

Diaphragm valves use a flexible diaphragm pressed down onto the seat to close off flow. They work well with corrosive or mildly abrasive slurries to provide throttling and control capability.

Additionally, valves can also be custom engineered for slurry control to meet specific requirements in mining applications.

Valve Comparison for Abrasive Slurry in Mining

Valve Type |

Best For |

Advantages |

Limitations |

| Knife Gate Valve | On/off slurry flow with high solids content | Cuts through thick slurry, cost-effective, rugged | Not suited for throttling, sealing surfaces wear quickly, potential leakage |

| Pinch Valve | Highly abrasive or corrosive slurries, large particle sizes | Only sleeve contacts slurry, low maintenance | Limited to medium pressure, sleeves must be replaced periodically |

| Ball Valve | Moderate slurry service where tight shutoff is needed | Compact, reliable sealing, quick quarter-turn operation | Seats wear quickly in abrasive service, prone to clogging in high solids |

| Diaphragm Valve | Corrosive or mildly abrasive slurries, flow control | Good corrosion resistance, suitable for throttling, simple maintenance | Diaphragms wear out fast with abrasives, not ideal for high pressure or coarse particles |

Best Practices for Extending Valve Life in Slurry Applications

Proper planning prevents poor performance, so here are a few best practices for extending valve life in slurry applications:

- Select valves designed specifically for slurry service

- Install valves in straight runs where flow is more predictable

- Regularly inspect and replace wear items before failure

- Train operators to avoid throttling with on/off valves

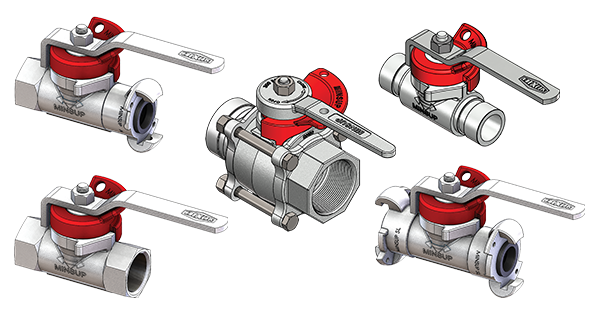

Dixon Valves for Mining Operations

- The Econovalve series of ball valves are solidly constructed and designed for rugged service such as the mining and construction industries. The unique one-piece ball and stem provides positive on/off action with no slack and no leaks.

Types

- Econovalve Sure-Lock Ball Valve

- Econovalve Grooved Ball Valve

- Econovalve Female Ball Valve

- Econovalve Female x Grooved Ball Valve

- Econovalve Female x Sure-Lock Ball Valve

Materials

- Body: spheroidal graphite cast iron to ISO 1083-1987; 400-250-15 SGI

- Seals: nitrile butadiene

- Handle: pressed mild steel

- Ball and stem: spheroidal graphite cast iron to ISO 1083-1987; copper chrome plated to AS1992

- Bolts: hex, M10 x 1.5 x 90, grade 8, black

- Nuts: hex, M10 x 1.5, grade 8, zinc plated

Specification

- Working pressure: 300 PSI at 70°F (21°C)

Frequently Asked Questions About Slurry Valves

- What is the best valve for abrasive slurry mining?

The best option depends on slurry composition, pressure, and maintenance needs. Depending on the specific application, knife gate, pinch, ball, or diaphragm valves are all potential slurry valve options. - How often should slurry valves be inspected?

In mining operations, slurry valves should be visually inspected during daily checks and undergo detailed inspections as part of scheduled maintenance. Replacing seals and other wear items before failure helps reduce downtime. - Can ball valves be used for abrasive slurries?

Standard ball valves are not ideal for heavy abrasive slurry because the seats wear quickly and can clog. However, specifically designed slurry ball valves, such as Dixon’s Econovalve series, can provide reliable shutoff in moderate slurry service. - How can I extend the service life of slurry valves?

Choose valves designed specifically for slurry service, install them in straight runs where flow is more predictable, and follow a regular maintenance schedule. Training operators to use each valve correctly also extends service life.

Summary

Whether it’s for commodities mined in the U.S. or global mining operations, valve failures in slurry lines are costly and potentially dangerous, but the right valve type, materials, and maintenance practices can significantly reduce downtime. Dixon provides rugged solutions for fluid handling in mining operations. For more information, visit dixonvalve.com or call 877.963.4966.