In industries where sanitary conditions are paramount, even the tiniest amount of bacteria can foul up entire operations. Compromised products, manufacturing downtime, and expensive cleanups are the unfortunate results. The dairy, food and beverage, pharmaceuticals, and personal care industries know this issue all too well.

One often overlooked component, where bacterial problems can arise, is the simple sanitary clamp, used to seal two ferrules together in a process line. Frequently, traditional single-pin clamps are tightened down too hard, squeezing the gasket into the ferrule and creating an intrusion. That’s a spot in the line where bacteria can potentially collect and proliferate. Not good. Under tighten the clamp and you could leave gaps between the ferrule and the gasket. Even if the connection doesn't drip, the gaps may trap material where clean-in-place processes cannot reach. Again, bacteria could collect.

Dixon's new, patent-pending Clever Clamp solves the issue of over or under-tightening by offering a new take on an age-old design. It relies on a lever to close the clamp, creating a perfect seal every time. With a quick spin of the material selection collar, the clamp adjusts to accommodate either rubber or PTFE gaskets, guaranteeing the correct compression and proper seal for either gasket material. It’s impossible to overtighten—or under tighten for that matter—because the clamp is preadjusted to the ideal level.

Consistent, Controlled Compression

Obtaining an ideal seal with traditional single-pin clamps means positioning the gasket between the ferrule flanges, aligning the bead of the gasket with the grooves of both ferrule flange faces, mating the faces together, and then applying the clamp. In a proper installation, the gasket is slightly compressed, and the bead is centered in the ferrule groove. The gasket's inside diameter should be aligned with the pipe's inside diameter so there is no intrusion or void. The alignment here is critical; it must be precise and even on all sides. Any irregularities will result in inconsistent or incomplete compression. When it’s time to tighten the clamp, a user employs a screwdriver or torque wrench, or another tool. This is sometimes where problems arise.

"It’s very common for people to overtighten a traditional clamp," says Brian Nguyen, a sales engineer with Dixon. "They're taking a screwdriver or tool to tighten it as much as possible. If they see a leak, they're going to tighten it even more, which makes the problem worse. But we've designed the Clever Clamp for consistent controlled compression," he says. "With the lever and cam design, it will bottom out at the exact compression required to not have the gasket intrude or have it too loose to cause leakage."

Getting proper compression in a line is vital to a well-running system. If there is not enough compression (the clamp is too loose), "you’re not getting a proper seal on that connection," says Nguyen. "It dramatically decreases the pressure rating of the line and you could have hazardous chemicals or hot liquid leaking or spraying out. Definitely not an ideal situation."

Overtightening a clamp not only creates intrusion by the gasket but can also depress a rubber gasket so much that it deforms and doesn’t bounce back into shape when the pressure is relieved. Remove the clamp for cleaning and you might have to replace the gasket adding time and cost.

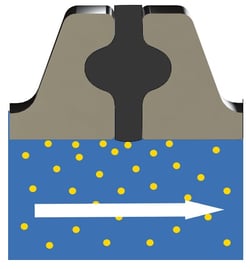

Proper compression

Proper compression

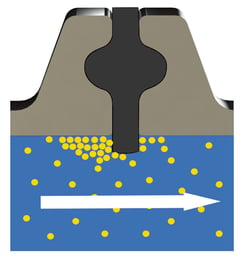

Over compression

Over compression

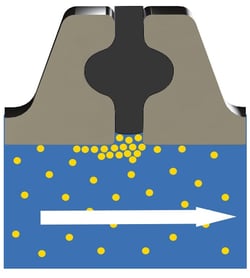

Under compression

Under compression

No Threads, No Extra Tools, No Problems

Threads can wear out over time. They just do. They get stripped or get gunked up with leaking product making bolts and/or wingnuts hard to tighten, leading to improper closing of a clamp. Threads also take time to tighten correctly. In situations with constant vibrations, threaded connections can sometimes unwind, leading to loose seals.

With the Clever Clamp, there are no issues with threads—because there aren't any. Instead of tightening a screw or wing nut on a single-pin clamp, a lever opens and closes smoothly, ensuring a tight connection. And because there are no threads to tighten, you don't need to carry a torque wrench or any other tool to dial in a specific torque setting. Changing multiple clamps in a line becomes much faster without having to take the time to get an exact torque rating for each clamp.

Tamper Resistant

Sometimes even the best-meaning employee opens a clamp they shouldn't have touched. Didn't realize the fermentation tank was half full before loosening up the clamp on a line at the bottom? It happens. Because nobody wants to lose valuable product, the standard version of the Clever Clamp offers a lockout-ready design, with aligned holes in the clamp body to make cable locking fast and easy. For an added layer of protection, the Clever Clamp offers an optional spring-loaded, self-locking pin, so the moment it's closed, it can't open again without a separate key. "It’s really an effective deterrent to make sure no one accidentally opens it," says Nguyen.

Another design benefit of the Clever Clamp is its low profile. There are no bolts or screws sticking out that could possibly get caught on a grate or snag other pieces of equipment. The Clever Clamp's lever sits perfectly flush with the rest of its stainless-steel assembly, reducing the chances of interference with other materials.

The Clever Clamp is also available with food-grade silicone, color-coded bands, which can be used in a variety of time-saving ways. One color could be used to distinguish which process line contains which fluid or which lines carry hot or cold liquid. Or use several colors to represent the order in which lines require maintenance. "In the sanitary field, people frequently need to take lines apart and clean them," says Nguyen. "With the color-coded bands, you now have a way to show which lines need to be cleaned at what intervals."

Made of 304 stainless steel, the Clever Clamp is available in 1-1/2", 2", and 3" diameters. It can be installed anywhere a traditional tri-clamp is used. "There's really nothing similar in the market," says Nguyen.

Watch our demo to learn more! Interested in a quote? Call 800.789.1718. We would love to help.