Run a comb through your hair and apply a dollop of Coppertone® to your face: voila, presto, you’re ready for anything! Bring on the day, you can handle it—at least, that’s how it used to be. These days, most of us require a much more complicated beauty regimen, with North Americans spending upwards of $35 billion annually on makeup products alone. Between Instagram influencers, un-aging Hollywood celebrities, and the endless rows of cosmetics displayed at our local drugstores, it’s clear that the beauty and personal care industry is big business.

But what has to happen before all that toothpaste, sunscreen, and mascara make their way into our bathroom drawers?

Take a closer look at the Crest or Colgate® sitting on your bathroom sink: can you name the ingredients inside that little plastic tube? Cleaning our teeth is a daily ritual, but unless you’re a dentist, most of us give very little thought to what goes on our brush bristles. Without looking, could you even say whether or not you last purchased tooth paste or tooth gel? (Hint: tooth gel is always colored, while toothpaste is white or striped).

Both the paste and gel prevent cavities, remove plaque, and clean our teeth—a process humans have been perfecting for over 4,000 years. Different cultures have used everything from green lead to fishbones, sand, and strong acids in an effort to have well-cleaned teeth, finally landing on the combination of materials we use today.

Binders, abrasives, foaming agents, various flavors, sweeteners, and more go into the modern American’s toothpaste. Fluoride, perhaps the most important ingredient in this cocktail of cleanliness, reduces decay while increasing tooth strength. And the difference between paste and gel? Gel tends to be less abrasive, making it a good choice for those worried about their tooth enamel, but otherwise cleans as well as traditional paste. Whichever one you purchase is truly a matter of preference.

How do all those ingredients get mixed up, shaken together, and transformed into that dab used to brush your teeth? Like many modern inventions, this magic happens in a factory.

While processing methods can vary, a typical toothpaste production line begins with liquid. Water and other liquid ingredients are mixed together first, then the pre-mixed dry materials are added in later—just like baking a cake. Fluoride, sweeteners, and preservatives are added next, followed by any abrasives. Toss in flavoring—anything from bacon to the traditional mint—and coloring, and it’s nearly done. Detergent, which gives toothpaste that foamy quality, is added last, slowly mixed in to prevent bubbling. If done correctly, all of this can happen in a couple of hours with each batch resulting in about 10,000 tubes of toothpaste.

All of this mixing happens in a large tank. Temperature, humidity, aeration, and agitation speed are closely controlled and monitored, and if even one of these variables is off, the taste or texture of the entire batch can be compromised. Aeration proves such a huge challenge that the majority of the mixing process takes place in a vacuum seal. To make this possible, rotating paddles are installed inside the tank itself: picture a giant, enclosed, mixing bowl. New ingredients are drawn into the tank without ever having to break the vacuum seal, completely eliminating the aeration problem. This method also provides hygienic benefits, since unwanted elements are never introduced to the toothpaste-in-progress.

All toothpaste is held to a food-grade level of safety, so it’s produced using the finest food-grade stainless steel. Stainless steel is also easy to clean, so it’s easy to imagine why it’s the most practical choice, given the thick, sticky, messy quality of toothpaste. Since consumers depend on consistency when purchasing their favorite brand of toothpaste, the durability of stainless steel, coupled with its ability to be disinfected between batches, makes it the perfect choice for toothpaste production.

Toothpaste, and all products that go in or on the body, are referred to in the U.S. as “sanitary” products and held to a very high standard. Manufacturers must ensure that all parts used in production- valves, fittings, hoses, tubes, and tanks- are all made of the required materials, such as stainless steel.

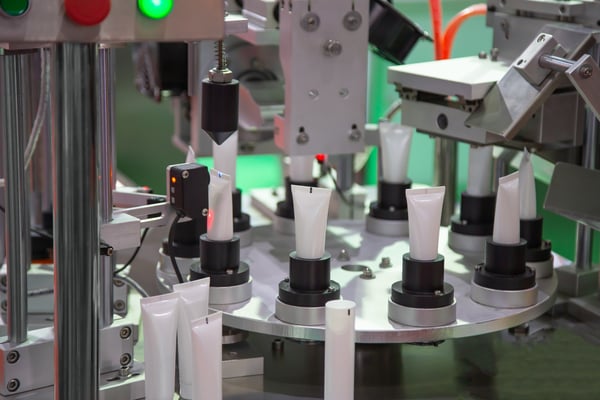

Cosmetic tubes filling and sealing machine.

Cosmetic tubes filling and sealing machine.

Toothpaste is just one of the thousands of products available to us. The average American woman uses 16 products on her face before leaving the house, while two-thirds of American men use daily skincare products. Sunscreen and deodorant are commonly used by all genders, making personal care a whopping $134 billion industry in 2016, which is expected to grow at a compound annual growth rate of 4.5% by 2025. With the emergence of Instagram influencers encouraging us to buy certain products, movie stars launching their own beauty lines, and a group of aging millennials discovering wrinkles in the mirror, that number is likely to grow.

All of these creams, gels, sprays, sticks, pastes, and lotions have to be produced, packaged, shipped, and sold before they make their way to your bathroom, and each requires a different process and set of equipment to make that possible. Meeting the current demand for these care products is an enormous task, requiring many hands and innovative technology to make it happen. Items like the vacuum-sealed tank used to create toothpaste are just the tip of the iceberg.

Take sunscreen, for example. With more and more people concerned about skin cancer, there has been a recent increase in the demand for sunscreen. Factories require special stainless-steel machines—like in the case of toothpaste—but using an entirely different process. Rather than mixing the materials with paddles, creams like sunscreen are made using a special mixer—picture an immersion hand blender instead of a stand mixer. Positive displacement pumps circulate the ingredients so they are evenly mixed throughout the compound. With the proper amounts of patience and control, factories are able to maintain texture and consistency, so the sunscreen bought in Albuquerque is the same as a bottle purchased in Honolulu.

Set of sunscreens: cream, oil and spray.

At Dixon, we’re proud to play a role in safely creating the products Americans need to stay clean, healthy, and feeling beautiful. From sunscreen production to deodorants, our valves and fittings are used all over the country in a variety of chemical processes, but toothpaste might be our favorite. After all, what else could bring us all together in such a refreshing, minty-green, smiley kind of way?

Learn more about Dixon’s full line of sanitary/hygienic stainless steel valves, sight glasses, reducers, clamps, and other sanitary fittings.

Do you have questions about your specific application? We're here to help, email a specialist.

Sources:

- https://www.quadroliquids.com/blog/how-makeup-is-made/

http://www.madehow.com/Volume-3/Toothpaste.html

https://carifree.com/2017/08/29/why-use-a-tooth-gel-instead-of-a-toothpaste/

https://www.wideopeneats.com/13-toothpaste-flavors-never-ever-exist/

https://www.huffpost.com/entry/how-much-is-your-face-worth-american-women-average_b_58befa65e4b06660f479e594

https://www.forbes.com/sites/andriacheng/2018/06/15/the-gift-your-dad-really-wants-this-fathers-day-anti-aging-cream/#11c8c633ba79

https://www.grandviewresearch.com/industry-analysis/us-personal-care-products-market

http://www.silverson.com/us/resource-library/application-reports/production-of-cosmetic-creams-and-lotions