Not many years ago, cryogenics – the production and behavior of materials at very low temperatures – was likely to be understood by a group of people with specialized knowledge in fields like aerospace.

Working with cryogenic applications means working with systems and components that have very special design and performance requirements. The costs associated with manufacturing and testing can be extreme. For these reasons, relatively few manufacturers have become adept at developing and commercializing cryogenic products that can meet the performance needs of the end user, at a price point that is practical.

By their very definition, cryogenic products need to perform in extremely low-temperature environments. For liquefied natural gas (LNG), the process of liquefying the gas reduces the volume by 600 times, making it far more economical to transport aboard LNG carrier ships to destinations around the world.

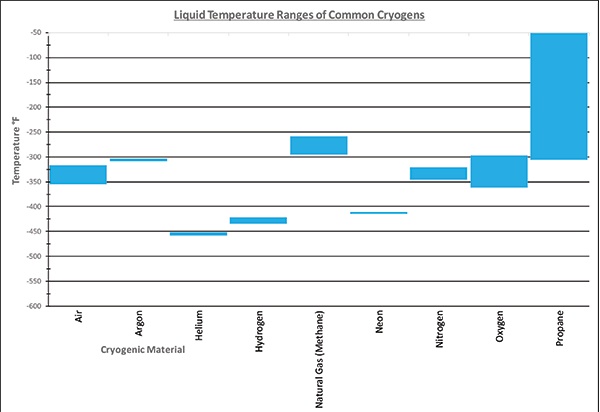

The temperature required to liquefy natural gas is -260°F (-162°C), which means that most pipe, valves, and fittings are specified to exceed that cryogenic temperature – typically in a range from -270°F to -325°F (-168°C to -198°C) (see Fig. 1)

Beyond low-temperature requirements is the need for the materials to work well in ambient temperatures, too. Being able to withstand frequent temperature fluctuations along with durability is essential. This means that cryogenic products must be made of low- or no-shrink materials that maintain (or even increase) their strength in extremely low temperatures.

Above: This image dramatically shows the impact on piping during a cryogenic cooldown period. Note the bowing of stainless steel pipe due to uneven thermal contraction. Designing products to operate properly in cryogenic conditions will reduce the risk of pipe features due to stress.

Above: Working in extreme-cold environments, operators can encounter highly unusual and problematic occurrences, such as liquefying air.

Designing products for cryogenic operating environments can be challenging but can be met with a special blend of engineering skills and practical application.

Read more about designing cryogenic products.