Whipping hoses can be life-threatening. At the very least, it is a costly disruption on a job site. Often, equipment can be damaged or destroyed, and operators injured. One way to prevent this from being an issue is to use hose restraints.

What are Hose Restraints?

Hose restraints are external devices that minimize damage to equipment and injuries to operators in the event that a hose, coupling, or clamp fails or if the assembly separates. They can be used to connect two hoses, a hose to a tool, or a hose to a fixed point, and prevent hose whipping. Hose restraints can be used in conjunction with, or in lieu of, safety check valves, depending on the application. Dixon offers three types of hose restraints.

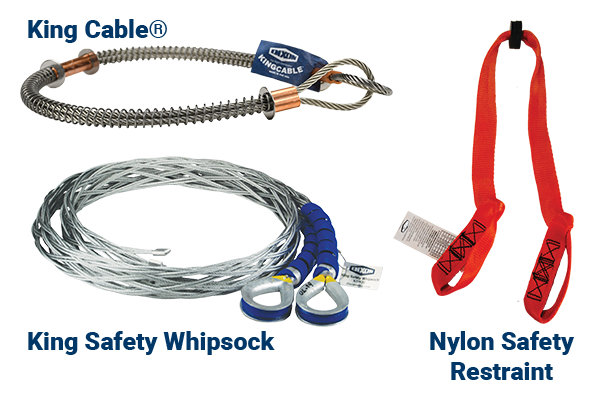

King Cable®

Made in the USA, King Cable is the most common type of hose restraint found on job sites. They feature spring-loaded loops that open easily to pass over the couplings for a firm grip on the hose. King Cables are available in hose-to-hose and hose-to-tool options and are rated for 200 PSI working pressure.

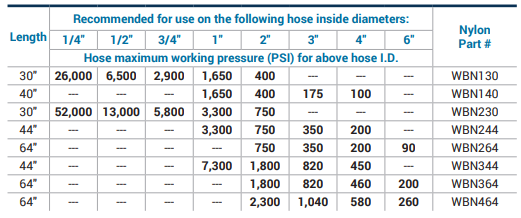

Nylon Safety Restraint

The strong, flexible webbing on nylon safety restraints offers superior corrosion and spark resistance over metal restraints. Nylon safety restraints are compatible with higher working pressures than traditional King Cables, up to 52,000 PSI, depending on the hose I.D.

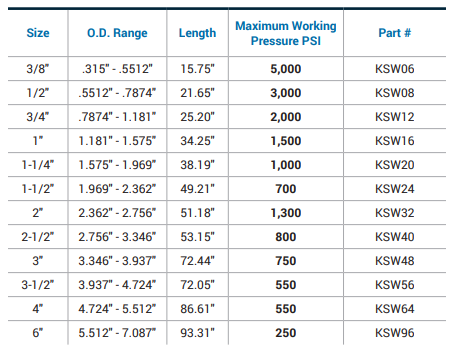

King Safety Whipsock

King Safety Whipsocks are ideal for applications at higher pressures ranging from 250-5,000 PSI, depending on the size. They are used with air, water, hydraulic, and slurry hoses. The galvanized steel woven stockings extend down the hose to grip securely over a large area and are secured to dual anchor points beyond the fittings.

Why are Hose Restraints Necessary?

Hose safety devices are required for a variety of reasons, including safety, compliance, equipment protection, and operational continuity.

The most critical reason to use hose restraints is to prevent injuries from hose whip. Additionally, hose safety restraints meet industry safety expectations and comply with OSHA standard 1926.302(b)(1). In the event of an accidental disconnection, hose restraints also reduce strain and damage to equipment. All of these factors combined can also help minimize downtime, costly accidents, and liability.

What Industries and Applications Require Hose Restraints?

Hose restraints play a vital role in compressed air safety, hose protection, and slurry transfer safety. Hose restraints are used in many applications, including:

- Chemical plants

- Construction

- Manufacturing

- Mining

- Oil and gas

In some applications, such as sand blasting or pile driving, 100% of the available air is required. OSHA requires safety restraints in lieu of safety check valves in these instances.

How to Choose the Right Hose Restraint?

All hose assemblies should be viewed as potential hazards. The proper selection and maintenance of hose, couplings, attachment devices, and accessories is imperative. Dixon recommends using the acronym STAMPED to guide the proper selection of hose assembly components.

Size: What is the I.D. of the hose? What is the O.D. of both ends of the hose? What is the overall length of the assembly required?

Temperature: What is the temperature range of the media flowing through the assembly? What is the temperature range of the environment that surrounds the outside of the hose assembly?

Application: How is the hose assembly actually being used? Is it a pressure application? Is it a vacuum (suction) application? Is it a gravity flow application? Are there any special requirements that the hose assembly is expected to perform? Is the hose being used in a horizontal or vertical position? Are there any pulsations or vibrations acting on the hose assembly?

Media: What is the media/material that is flowing through the hose assembly? Being specific is critical. Check for: abrasive materials, chemical compatibility, etc.

Pressure: What is the maximum pressure, including surges, that this hose assembly will be subjected to? Always rate the maximum working pressure of your hose assembly by the lowest rated component in the system.

Ends: What couplings have been requested by the user? Are they the proper fittings for the application and the hose selected?

Dixon®: Dixon recommends that, based on the hose, fittings, and attachment methods used, all assemblies be permanently marked with the designated working pressure and intended media. Do not use other manufacturers’ fittings or ferrules with Dixon products due to the differences in dimensions and tolerances. We also recommend that all hose assemblies be tested frequently.

Installation and Maintenance Best Practices

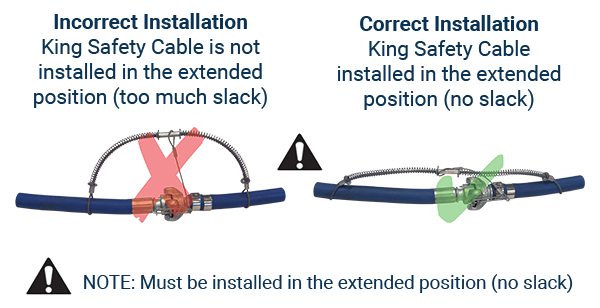

Ensuring correct installation is key to using a hose restraint properly.

King Cables must be installed with no slack so that if two hoses disconnect, the momentum they carry will be minimal before the King Cable engages.

Nylon safety restraints are installed similar to King Cables with no slack and use rubber grommets to securely choke eyes around the hose.

Nylon safety restraints are installed similar to King Cables with no slack and use rubber grommets to securely choke eyes around the hose.

King Safety Whipsocks secure both eye-to-rigid or eye-to-eye anchor points. Dixon recommends using two King Safety Shackles with King Safety Whipsocks to connect two hoses or a hose to a fixed location. Remember, the working load must be rated for the application.

Hose restraint systems, as well as hose assemblies in general, should be inspected regularly for wear, corrosion, or broken strands. Be sure to replace hose restraints immediately if damage is visible or after heavy use in critical applications.

What are the Consequences of Not Using Hose Restraints?

Not using hose restraints has the potential for various consequences ranging from the inconvenience of legal and compliance issues, such as OSHA fines for violations, to the severity of injuries and fatalities. Additionally, equipment can also be damaged, which may require costly repairs and result in a loss of productivity due to unplanned downtime.

FAQs: Hose Restraints

- What is a hose restraint?

A hose restraint is a safety device designed to prevent a pressurized hose from whipping if a coupling or fitting fails. - Why are hose restraints important?

They protect workers from injuries, reduce equipment damage, and help companies comply with OSHA safety standards. - What types of hose restraints are available?

Common options include King Cables®, nylon restraints, and King Safety Whipsocks. - How do you choose the right hose restraint?

Consider the hose diameter, working pressure, media being conveyed, and the environment (abrasive, corrosive, or extreme temperature conditions). - How often should hose restraints be inspected or replaced?

Inspect them regularly for wear, corrosion, or broken strands. Replace immediately if damaged.

Summary

Hose restraints are a small investment with a major safety impact. Protecting personnel and equipment, and improving operational efficiency, hose restraints are essential for industrial hose safety and compliance. To learn more about Dixon’s hose restraint options, visit dixonvalve.com or call 877.963.4966.