Overview of Flare Fittings

Flare fittings are a type of compression fitting used with a flared piece of tubing. They are secured in place with a sleeve and nut to create a pressure and leak-resistant seal. The tip of the flare fitting is engineered to precise angles according to specific industry standards for optimal performance and reliability.

What are JIC Flare Fittings?

JIC flare fittings follow the standards set by the Joint Industry Council, which is where the acronym comes from. They were the first fitting to become standardized. JIC fittings were originally developed during World War II to meet the need for reliable, durable, high-pressure fittings used in extreme military conditions. Beyond the battlefield, JIC fittings are found in manufacturing environments and the aerospace industry.

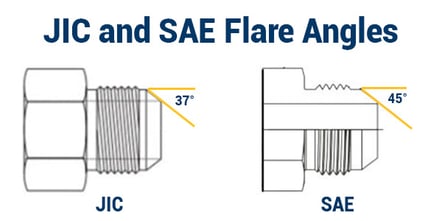

JIC flare fittings are mostly used in hydraulic and fluid-transfer systems. They are similar to Army-Navy (AN) fittings but are not produced with as strict tolerances. JIC fittings feature a straight thread with a male and female component. Each component has a 37-degree seat with a flared male seat and a coned female seat, typically with standard thread sizes. JIC flare fittings are made with stainless steel, brass, carbon, and nickel alloys. They are easy to connect and disconnect and are suitable for high-pressure applications.

What are SAE Flare Fittings?

SAE flare fittings were developed by the Society of Automotive Engineers, originally to meet the needs of the automotive industry. Original applications included use on fuel lines, brake systems, and hydraulic clutches.

SAE fittings are designed to be versatile and cost-effective for mass production. They come in different materials but most are brass. SAE fittings have different seat angles. SAE J514, which is common in hydraulic applications, comes with a 37-degree flared male seat, the same as JIC flare fittings. The most popular SAE fitting, SAE J512, is common with automotive pipe systems and comes with a 45-degree flared male and female seat. SAE fittings are common in low-pressure applications and are available in a range of customizable thread sizes.

Are JIC and SAE Flare Fittings Compatible?

Although JIC and SAE flare fittings may look similar, it is important to remember they have different design specifications and pressure ratings. Therefore, it is not recommended to interchange JIC and SAE fittings. However, there is one exception to this rule. Dixon offers a female 45° SAE/37° JIC swivel x push-on hose barb with a dual angle seat making it compatible with both SAE and JIC flare fittings.

Identifying JIC and SAE Flare Fittings

Properly identifying JIC and SAE flare fittings is critical for optimal performance and safety. The first step to identify the fitting is to measure the flare angle. The flare angle is measured at the end of the fitting with a protractor. Flare angle is the most important feature that distinguishes the two types of fittings. The second step is to determine the thread size and pitch. This is done with a thread gauge.

Dixon Flare Fittings

Dixon offers JIC and SAE flare fittings for hose barbs, push-on hose barbs, and hydraulic adapters.

Male 37° JIC Flare x Male NPTF

Specifications:

- Reference SAE 070102

- Pressure rating at 70°F (21°C)

JIC 37° Flare Cap

Specifications:

- Reference SAE 070112

- Pressure rating at 70°F (21°C)

90° Male JIC 37° Flare x Male NPTF Elbow

Specifications:

- Reference SAE 070202

- Pressure rating at 70°F (21°C)

SAE 45° Flare Male Connector

Specification:

- Temperature range: -65°F to 250°F (-54°C to 121°C)

SAE 45° Flare Female Connector

Specification:

- Temperature range: -65°F to 250°F (-54°C to 121°C)

SAE 45° Flare Female Elbow

Specification:

The products listed above are just a small sampling of Dixon’s JIC and SAE flare fittings. For recommendations on your specific application, visit dixonvalve.com or call 877.963.4966.