Whether it's for watering a garden, putting out fires, or pumping gasoline, hoses play an important role in our daily lives. In a previous blog post, we discussed hose assembly dynamics. Another often overlooked aspect of hoses, however, is the attachment method used on the end.

Overview/Applications

There are three options for transferring fluid from one location to another: hose, pipe, and tubing. Hoses are flexible, portable structures composed of several layers of different materials depending on the application. Pipes and tubing are rigid cylinders made of mainly one solid material. Tubing is generally thinner and measured by the outside diameter (O.D.), while pipe is measured by the inside diameter (I.D.). Although they differ structurally, hoses and pipes both require some type of connection to direct the flow of the desired media.

The type of fitting and its specifications depend on the application: hydraulic or pneumatic. Hydraulic fittings support the transfer of liquids under pressure, while pneumatic fittings are used to transfer gas or air under pressure.

Types of Connections

Hose and pipe connections can be classified as couplings or fittings. Couplings, as the name implies, are coupled together with male and female ends as a unit or pair. Fittings are stand-alone connections that are threaded onto the hose or pipe. All couplings are considered fittings, but not all fittings are couplings.

The different types of connections are differentiated based on the connection and function. The most common types of hose connections are cam & groove, compression, flange, flare, quick disconnect, and threaded.

Cam & Groove

Cam & groove couplings are inserted into the hose or pipe and the cam arms hold the coupler and adapter together. There are a variety of cam & groove options available. Check out our Cam & Groove Comparison blog post to learn more.

Compression

With compression fittings, a nut and ferrule are threaded together and compressed on the ferrule. Learn more about compression fittings in this blog post: Basics of Compression Fittings.

Flange

A flange is a port with a flush face that attaches to the hose or pipe. Flanges are attached via clamps or bolts.

Watch this video to learn more about pipe flanges.

Flare

A flare is a type of compression fitting with a tapered end. The threading is used to hold the fitting together and the flare refers to the wide sealing surface used to prevent leaks. This hose connection method is best suited for high-pressure applications.

Quick Disconnect

Quick disconnects replace fitting connections that require tools. This type of connection is quick and the connection is easily made by hand. Most quick disconnect fittings feature a spring-loaded ball latching mechanism to automatically lock the two halves when they are pushed together. To release, the sleeve is retracted, and the balls are unloaded. Others, such as Dixon’s Air King® use a simple twist motion to connect the two halves.

Threaded

Threaded fittings connect with matching threads. Male connections have threads on the outside, like a bolt, while female connections have threads on the inside, like a nut. Threads can be straight or tapered, and come in a variety of different types including NPSH, BSPP, NPT, and BSPT.

Learn more about thread types and compatibility in this video.

Methods of Attachment

Hose and pipe fittings can be attached in different ways. Whether it's with a clamp, crimp, internal expansion, or swage, ensuring a fitting is properly attached to a hose, pipe, or tube is crucial.

Preformed Band Clamps

Band clamps retain couplings in industrial hose applications. The buckles should be offset around the hose to eliminate the possibility of a straight-line leak. A band clamp hand tool is used for application.

Bolt Style Clamps

Bolt-style clamps are designed to bend while tightening. The clamp halves bend around the hose when it reaches the recommended torque rating. For this reason, it cannot be reused and is a single-use clamp.

Crimp

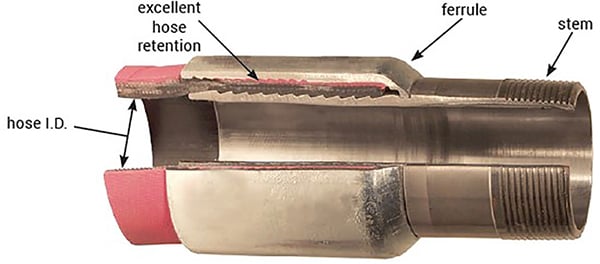

With crimp fittings, the hose is compressed between the crimp sleeve and hose shank to make the attachment. A crimper is used which closes around a ferrule or sleeve on a fitting, changing the circumference and length simultaneously, to reduce it to a predetermined outside diameter (O.D.)

One of the many interactive tools on the Dixon website is the Crimp Tool, which allows users to select a hose I.D., O.D., and fitting style to identify the proper Dixon part and compatible parts.

Swage

Using a ram, a fitting and ferrule are pushed through a fixed split die bed to reduce the O.D. of the ferrule, compressing the hose into the stem serrations. As a result, the fitting is permanently attached to the hose. Need assistance? Use our online swage tool.

Internal Expansion

With internal expansion, the coupling body is pushed from the inside out, permanently locking the hose between the ferrule and the expanded hose stem. This creates a full-flow path for the media.

Function of Fittings

Different fittings have different functions that serve valuable purposes. Fittings can be used to extend, end, add or change direction, connect jump sizes, or make special connections.

Specifications

Specifications

The sizing, operation, and materials of hose attachment methods must be considered carefully to ensure the proper fitting is selected for the application.

Sizing

Hose and pipe fittings are available in a variety of sizes. Choosing the proper size of any connection is essential for safety and efficiency. It is important to accurately measure the hose I.D. and O.D. to determine what size fitting is required. Watch our How to Use a Dixon Diameter Tape video to help with this process.

Operation

Pressure and temperature are two important factors to consider when selecting the proper hose attachment method.

The working pressure of a fitting specifies the range or maximum pressure a fitting was designed to operate. This pressure, expressed in pounds per square inch (PSI), must be adhered to in order to prevent the fitting from breaking, leaking, or losing its seal.

Pipe and hose fittings also have a temperature range that specifies what temperature the fitting was designed to operate at. This is measured in degrees Fahrenheit (°F) or degrees Celsius (°C). Not adhering to the operating temperature range can cause the fitting to fail.

Following the working pressure and temperature ranges of a fitting is imperative for safety and efficiency in any application.

Materials

Hose attachment methods are available in a variety of different materials depending on the application. Factors such as cost, environmental conditions, flexibility, media, operating pressure, and temperature should always be considered when selecting a material.

Hose and pipe fittings can be made of metal, such as aluminum, brass, steel, and stainless steel. In addition, fittings can also be made with plastics such as polyethylene and polypropylene.

Summary

Dixon is committed to providing The Right Connection® for your application. Our wide range of hose and pipe fittings serves the agriculture, chemical processing, construction, oil and gas, fire protection, food and beverage, maintenance and repair, mining, steel processing, and transportation industries.

For more information about hose attachment methods, visit dixonvalve.com, or contact a Dixon specialist for recommendations on your specific application.