In the 1860s, Napoleon III, emperor of France, had a problem. French wine was turning sour, and no one knew why. In France, when the wine goes bad, everything goes bad. So, the emperor turned to France’s greatest scientist, Louis Pasteur.

Pasteur had a theory, not widely accepted at the time, that living things too small to see were at the heart of the matter. Peering at samples of wine in a microscope, he noted that good wine showed plenty of plump, round cells, while the spoiled samples were replete with longish, rodlike cells.

We now know these plump cells to be yeast and the rodlike ones to be Mycoderma aceti, a bacterium known as “the mother of vinegar.” Pasteur’s discovery was so profound that he overturned conventional wisdom in winemaking that believed the transformation from grape juice to wine was a chemical process, not biological.

Portrait of Louis Pasteur in his laboratory; Photo courtesy of iStock, pictore

Portrait of Louis Pasteur in his laboratory; Photo courtesy of iStock, pictore

Pasteur then went one step further and devised a way to kill the harmful microbes, all without affecting the flavor or appearance of the wine. It was the birth of the patented process known today as pasteurization, named in his honor.

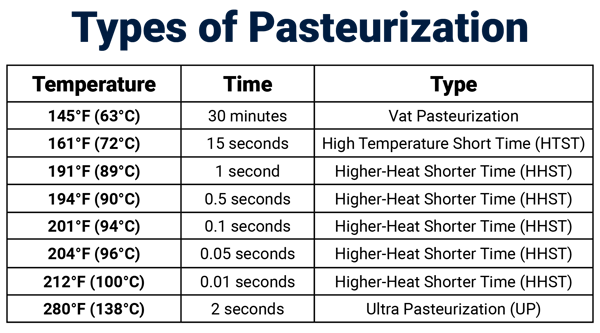

The act of pasteurization could not be simpler, nor the results more profound. The food product is heated to a specific temperature for a prescribed time and cooled, killing most if not all of the disease-causing microbes lurking within. Pasteur was not the first to show that heat could preserve foods and beverages, but he standardized the process by describing the exact temperatures and time necessary to rid foods of specific harmful microbes.

With milk, for instance, pasteurization initially called for heating to 155°F to 178°F—not quite boiling—for a mere instant. Temperature standards were later adjusted downward, but for a longer time, to kill the bacteria responsible for tuberculosis and Q fever.

Pasteurization is perhaps now best known for its impact on the dairy industry. Bacteria borne by milk have been shown to cause sometimes life-threatening diseases, such as listeriosis, typhoid, tuberculosis, botulism, diarrhea, cholera, diphtheria, and brucellosis, among others. All can be neutralized by pasteurization.

Despite Pasteur’s success as a savior of the French wine industry, commercial pasteurization of milk did not arrive for three decades and, even then, proved controversial, as people thought it would compromise milk’s flavor, nutrients, and color.

In 1908, Chicago passed the first law in the United States mandating pasteurization, which was overturned two years later, and it was another four decades before Michigan became the first state to pass such law. Pasteurization is almost universal today in the U.S.

Modern Pasteurization

Of course, Pasteur could never have guessed the broad-ranging impact his discovery would have when he shared it with Emperor Napoleon and his men at the royal residence. Today, everything from milk and cream to orange juice and beer are pasteurized. Surprisingly, however, wine is rarely pasteurized anymore, as it compromises its desirable process of aging.

There are different types of pasteurization depending on the length of time a product is heated to a specific temperature.

Dixon Products for the Food and Beverage Industry

Pasteurization, along with other food and beverage processes, require high-quality products for safety and efficiency. Dixon provides a variety of hygienic solutions to support this market.

BC/BP-Series Sanitary Centrifugal Pump

- Casing is stamped, not cast, for lighter weight and less porosity

- Safer cage-less guard design

- BC-series features impeller retainer

- BP-series featured threaded impeller nut

Specifications

- Nominal capacity up to 1200 GPM

- Temperature range: 32°F (0°C) to 212°F (100°C)

- Nominal speed: 3500 RPM (60 HZ)

- F-seal - cascade flush option for D or DG seal

- 100% CIP-able

- Uses standard 4” tube clamp for easy removal and adjustment of the casing

- Efficient seal path promotes seal cooling and provides less restrictions to adequately clean the seal

- Sealed impeller provides optimal hygienic performance while the split shaft compression collar improves shaft concentricity, reduces vibration, and improves seal life

- Drop-in replacement for other C-100 series pumps

ExD-Series Sanitary Centrifugal Pump

- Externally balanced seal with clamped in seat

- Unique adapter slots make pump discharge easily adjustable from 90° to 180° without casing or front cover disassembly

- Wet end mounts to a standard NEMA C-face frame motor

Specifications

- Minimum operating temperature: 32°F (0°C)

- Maximum operating temperature: 212°F (100°C)

- Viscosity range: 1-500 cP

- Nominal capacity: up to 500 GPM

- Nominal speed: up to 3500 RPM - 60 Hz

Features

- Bi-wing rotors to maintain efficiency even with low-viscosity products

- 25 Ra finish meeting EHEDG and 3A specifications

- 100% CIP-able

- Stainless steel shims between the gear box and casing

Specifications

- Front-loading seal options:

- Single (standard) and double mechanical seals, TC vs TC (standard)

- Triple lip seal

- Flush options available on all seal types

- Hex head body bolts eliminate cavities of socket head screw

- High performance seat design increases seal life

- Large disc stem decreases chance of stem deformation

- Large range of options for operating devices and accessories

Specifications

- Standard connections: clamp, weld

- Operating temperature: 15°F to 200°F (-9°C to 93°C)

- Maximum pressure:

- 1/2” to 2”: 140 PSI

- 2-1/2” to 3”: 110 PSI

- 4”: 85 PSI

- 6” to 8”: 60 PSI

Features

- FDA Title 21 compliant

- Cartridge options: melt blown, high efficiency pleated, carbon block, and polyether sulfone

Specifications

- Micron ratings:

- DF-MB-Series: 1, 5, 10, 20, 25, 30, 50, 75, and 100

- DF-PHE-Series: 0.2, 0.45, 1, 3, 5, 10, 25, and 50

- DF-CB-Series: 1, 3, 5, and 10

- DF-PES-Series: 0.1, 0.22, 0.45, 0.6, 0.8, 1.2, and 5

Read Filters and the Purification Process to learn more about Dixon’s sanitary filters.

- Easy to assemble and disassemble

- Patented single clamp construction

Specifications

- Product contact metal components: 316 stainless steel

- Non-product contact metal components: CF8

B54BM-Series Compact Sight Glass

- Compact design for hose assembly

- Less cost to repair than bolted styles

Specifications

- Operating temperature: 0°F to 200°F (-17°C to 93°C)

- Working pressure:

- 1”, 1-1/2”, and 2”: 145 PSI

- 3”: 120 PSI

- 4”: 95 PSI

- 3A certified for COP

- Easy assembly/disassembly

- Multiple body styles for greater process flexibility

Specifications

- Maximum pressure at 70°F (21°C)

- 1” and 1-1/2”: 500 PSI

- 2”: 450 PSI

- 2-1/2”: 400 PSI

- 3”: 350 PSI

- 4”: 300 PSI

- Maximum pressure at 200°F (93°C)

- 1” and 1-1/2”: 300 PSI

- 2”: 250 PSI

- 2-1/2”: 200 PSI

- 3”: 175 PSI

- 4”: 150 PSI

Summary

Although it was originally developed to preserve wine, pasteurization quickly became essential in ensuring the safety of milk, juices, and other products. As the food and beverage industry continues to rely on this process, Dixon plays a key role by supplying hygienic components to maintain the cleanliness, efficiency, and reliability of pasteurization systems.

For more information, visit dixonvalve.com or call 877.963.4966.