When using a portable air compressor on a work site, what component should (almost) always be part of the job? The answer is a safety check valve (SCV), properly installed between the compressor and the hose. In fact, if your air hose has an inside diameter of more than a ½ inch, OSHA requires an SCV to be installed at the source of the air supply to shut off the air automatically in case of hose failure. (If a check valve is not being used, OSHA requires a safety cable, such as Dixon’s King™ safety cable, to be attached to the hose.) But selecting the right safety check valve is an important but often times confusing task. There are many factors that play into that decision: air pressure, tool flow rate, compressor flow rate, the size of your hose, and the length of your hose, among them. Here’s a quick guide to helping make that decision an easier one.

How exactly is a safety check valve used?

Safety check valves are used to shut off flow in the event of a full-flow condition, which could be caused by a line break or damaged tool. During a full-flow condition, the compressor blasts air like a geyser and can whip the hose around the worksite, potentially causing serious injury to personnel or damage to equipment.

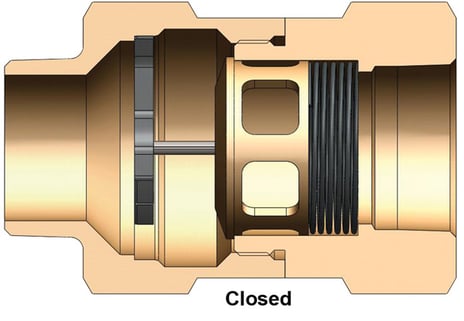

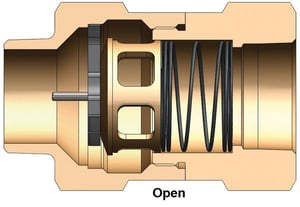

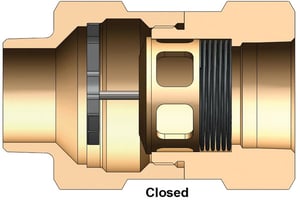

How does a safety check valve work?

As air passes through the safety check valve, the valve flutters back and forth, allowing the air to bypass the valve and go downstream to the tool. In the event of a hose failure, the sudden rush of air through the valve causes it to slam shut, eliminating potential danger. A pin-sized hole in the valve allows a small amount of air to escape, but not enough to whip the hose around. That’s why you’ll still hear some air hissing at the end of the hose, even when the safety valve is engaged. Once the hose is repaired and the full flow condition goes away, the safety check valve will reset itself, allowing airflow to resume. Without this feature, you would have to manually reset the valve, a time-consuming task.

How do you select the correct safety check valve for the job?

Before deciding which safety check valve to use, you’ll have to answer the following questions:

- What is the inside diameter (ID) of the hose you want to use?

- What is the operating pressure of the compressor in PSI?

- What is the standard cubic feet per minute (SCFM) of the compressor? (That information is usually printed on the side of most air compressors.)

- How much airflow, in SCFM, does the tool(s) require to operate properly?

- What is the maximum airflow possible, in SCFM, through your air hose, at the end of the length of the hose? (Note: If the hose you’re using is more than 100 feet long, contact Dixon for recommendations.)

Those are the general questions you need to ask before selecting a safety check valve, but there are also several other factors to consider:

- It’s very important to select both the correct hose ID as well as the correct size spring within the valve. If the spring is too large or too small, it will cause the valve to shut prematurely or not to check at all.

- The safety shut-off valve taper (NPT) size must be the same as the nominal ID size of the airline on which it is used. (Note: Never increase or decrease the hose size from the compressor to the tool or from the compressor to the manifold.)

- To avoid nuisance cut-offs, the SCV selected should have a cut-off range of 110% of the maximum anticipated airflow to the tool, or tools, to be used. (As a general rule, you want your tool consuming less flow than the cut-off range of the SCV and you want your compressor capable of supplying more flow than the cut-off range of the SCV.)

- The maximum SCFM of the supply-side airline must be above the cut-off range of the valve. The cut-off range of Dixon's shut-off valves is given at 90 PSI. To determine the cut-off range at other PSIs, please refer to Dixon’s Cut-off Rate Chart on our product spec sheet.

- In certain applications, like pile driving or sandblasting, where a surge of air is needed right away, you’ll have to use a safety cable since a check valve won’t work properly.

In closing, whenever you’re using an air compressor for jobs other than the ones mentioned directly above, it’s important to include a safety check valve in the system. Knowing how to select the proper SCV for the job creates a safer, more efficient worksite. As always, if you have any questions about safety check valves, please call a Dixon representative at 877.963.4966.