What do a gallon of gasoline, a ream of paper, and a can of corn all have in common? Each of these items requires steam for production. From oil, gas, and paper, to food, beverages, and textiles, steam is an important aspect of the manufacturing process for a variety of applications and industries.

History

The first steam engine was developed in England by Thomas Newcomen in 1712. By 1730, steam engines were common in western Europe. They were mainly used in mines to pump out water.

In 1769, James Watt, a Scottish engineer, made significant improvements to the steam engine, making it more efficient than earlier models in terms of power and fuel consumption. Progress continued with the invention of the first locomotive steam engine in 1802.

The development of the steam engine played a significant role in history by sparking the Industrial Revolution. Semi-automated factories were created and the implementation of coal-fired steam engines on railways and ships expanded international trade.

Products Recommended for Steam Service

Although its history dates back hundreds of years, steam is still widely used today. While valves, fittings, and other fluid transfer and control products are useful in a variety of applications, it is important to note that not all products are designed for use with steam. Dixon offers a diverse product range that includes steam-safe products.

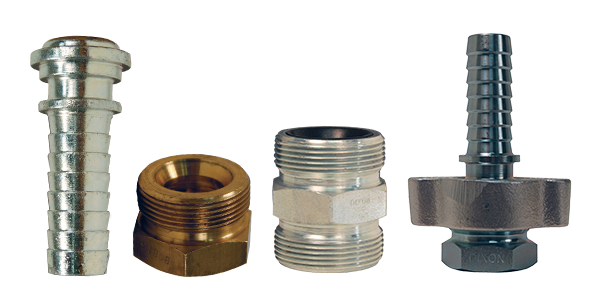

Boss® Ground Joint Fittings

Application

- Boss ground joint complete couplings supply a convenient threaded fitting to connect two lengths of hose, or a single length to a male or female threaded outlet

- Use with Boss clamps

Features

- The stem part that is clamped to the hose is one-half of the Boss ground joint connection. The Boss ground joint spud part of the coupling serves as the other half and is usually fixed to the equipment. The two halves are connected or disconnected by rotating the wing nut of the spud. When connected they achieve both a mechanical and a pressure seal

- A leakproof seal forms when the metal head of the stem makes contact with the patented polymer seat in the Boss ground joint spud

- Easy to seal

Specification

- Recommended for steam service up to 450°F (232°C)

Boss® Clamps

Application

- Bolts in Boss clamps are designed to bend as they are tightened. This allows the clamp to conform to the hose's outside diameter (O.D.)

- Always tighten bolts to their specified torque value

- Periodic re-tightening of bolts is required due to the “cold flow” phenomenon present in all rubber hose

- Designed for single use only. Once removed they are to be discarded

Features

- 2 bolt and 4 bolt

Specifications

- Recommended for steam service up to 450°F (232°C)

Boss® Crimp Steam Fittings

Application

- Safe and reliable steam fittings designed, tested, and Dixon-approved for use with the following steam hoses: Continental Flexsteel® 250, Gates Plant Master® Steam, and Texcel® Tex-Steam

Features

- NO-skive fitting system for ease of fabricating hose assemblies

- Bite-the-wire crimp ferrules for long-lasting fitting retention

- Positive metal-to-polymer seal in ground joint couplings

- Non-metallic polymer seal resists most chemicals found in manufacturing facilities

- A leak-proof seal forms when the metal head of the steam makes contact with the patented polymer seat in the spud

Specifications

- Temperature range: -40°F to 450°F (-40°C to 232°C)

- Benchmark and ISO 4023/6135 standards

- Test methodology simulates transfer applications as defined in industrial operations

- Dixon steam test methodology and parameters available on request

Want to learn more? Check out our Boss Crimp Steam playlist on YouTube.

HS-Series Hydraulic Couplings

Application:

- Designed exclusively for steam applications

Features:

The coupler has a large plated steel sleeve designed for easier gripping with gloves

Specifications:

- Special high-temperature EPDM O-rings designed for steam service providing a temperature range of -70°F to 400°F (-57°C to 204°C)

- Rated to 200 PSI gauge saturated steam 382°F (194°C)

Dixon MannTek Dry Disconnects for Steam Service

Application

- Designed to fit hoses carrying steam used in chemical (heating), pharmaceutical (disinfection and sterilization), and loading bays

Features

- Lockable versions are available on 1-1/2” and 2”; contact Dixon

- Couplers supplied with double handles

- Performance unaffected by surface rust

Specification

- 150 PSI at 350°F (177°C)

F8-Series Bellows Sealed Globe Valves

Application

For use in applications where leakage into or out of the valve is unacceptable such as heat transfer oil, toxic fluids, steam, and regulated media

Features

- Welded bonnet

- Classes: 150, 300, 600, and 800

Specifications

- End configuration: socket weld, threaded, or flanged

- Basic design: API 602

- End flange: ASME B16.5

- Threaded ends: ASME B1.20.1

- Face to face: ASME B16.10

- Bellows: MSS SP-117

G8-Series Bellows Sealed Glove Valves

Application

- For use in applications where leakage into or out of the valve is unacceptable such as heat transfer oil, toxic fluids, steam, and regulated media

Features

- Bolted bonnet

- Classes: 150, 300, 600, and 800

Specifications

- End configuration: socket weld, threaded, or flanged

- Basic design: API 602

- End flange: ASME B16.5

- Threaded ends: ASME B1.20.1

- Face to face: ASME B16.10

- Bellows: MSS SP-117

H8-Series Bellows Sealed Gate Valves

Application

- For use in applications where leakage into or out of the valve is unacceptable such as heat transfer oil, toxic fluids, steam, and regulated media

Features

- Welded bonnet

- Classes: 150, 300, 600, and 800

Specifications

- End configuration: socket weld, threaded, or flanged

- Basic design: API 602

- End flange: ASME B16.5

- Threaded ends: ASME B16.10

- Face to face: ASME B16.10

- Bellows: MSS SP-117

W8-Series Bellows Sealed Gate Valves

Application

- For use in applications where leakage into or out of the valve is unacceptable such as heat transfer oil, toxic fluids, steam, and regulated media

Features

- Bolted bonnet

- Classes: 150, 300, 600, and 800

Specifications

- End configuration: socket weld, threaded, flanged

- Basic design: API 602

- End flange: ASME B16.5

- Threaded ends: ASME B1.20.1

- Face to face: ASME B16.10

- Bellows: MSS SP-117

Note: While the F8-Series, G8-Series, H8-Series, and W8-Series forged bellows sealed valves are all compatible with steam service, most users prefer the welded bonnet of the F8-Series and H8-Series for steam.

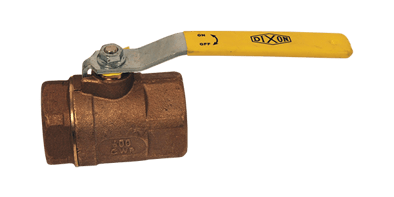

250 Lb. Steam Ball Valve

Application

- Recommended for use with fluids with widely varying temperatures and/or thermal expansion rates

Features

- Vacuum service to 29 inches Hg

- Blow-out proof stem design

- Adjustable packing gland

Construction

- Bronze body

- 316 stainless steel ball and stem

- Multi-fill RPTFE seats

- Multi-fill stuffing box ring

- High-temperature MPTFE stem packing

Forged Steel Gate Valve

Application

- Can be used for steam service

Features

- Class 800

- ASTM A105, ANSI B120.1

- Bolted bonnet

Specifications

- Pressure rating: 1975 PSI

- Maximum temperature: 800°F (427°C)

Forged Steel Globe Valve

Application

- Can be used for steam service

Features

- ASTM A105, ANSI B120.1

- Bolted bonnet

Specifications

- Class 800

- Pressure rating: 1975 PSI

- Maximum temperature: 800°F (427°C)

180° Steam Gauge Siphon

Application

- Used to protect temperature sensors, or other sensitive detection devices, from high-temperature media like steam

- Recommended for applications involving temperatures above 100°F (37°C).

Specification

- Complies with ASTM B-43

Summary

Whether it’s for use at a utility station in a refinery or another application, using steam safely and minimizing leaks are imperative for the success of any operation. Dixon is delighted to provide a variety of products compatible with steam service. When it comes to service, reliability, and innovation Dixon is your best choice.

For recommendations on your specific application, call 877.963.4966 or contact us online.