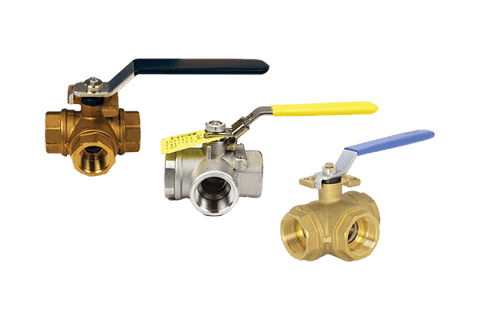

When it comes to fluid control, the key is to go with the flow—and 3-way ball valves make it easier to do just that. These versatile valves allow for precise regulation of flow in multiple directions, making them essential for a variety of industries.

Overview of 3-Way Ball Valves

Ball valves are one of the many valves used in sanitary and industrial applications. Inside the valve is a ball with a bore through the center to control and regulate flow in multiple directions. As the name suggests, 3-way ball valves have three ports for the diversion and mixing of flow paths. There are two configurations: L and T. The configuration is determined by the ball inside the path and the shape of the ball flow path.

L vs T: Key Differences

L-flow 3-way ball valves control flow at a 90° angle between two ports at a time. They are used for simple switching applications to alternate flow between outputs and can shut-off flow if needed. Common applications include industrial processes and switching between water sources in irrigation systems.

T-flow 3-way ball valves allow flow in multiple directions with the ability to mix or divert flow between 3 ports. They are used to blend fluids and switch between two sources. Unlike L-flow, T-port valves cannot shut off flow completely. Some example applications include HVAC systems, mixing hot and cold water for precise temperature control in plumbing systems, and blending controlled proportions of chemicals for processing.

Factors to Consider When Selecting a 3-Way Ball Valve

Knowing when to use an L-flow or T-flow valve is dependent on the flow requirements, system design, and operational needs.

Rotating the ball inside a 3-way valve will yield different flow paths. The requirements of the application, whether it’s simple diverting or if mixing flow paths is necessary, will determine the flow path needed when purchasing a multiport valve. Flow capacity should also be considered for optimal performance.

When a multiport ball valve is ordered with a manual handle, adjusting the flow path for the application may be as simple as rotating the valve by hand. However, when a 3-way ball valve is actuated, the flow path information is required to ensure the valve and necessary components are built in the proper position to meet the application requirements.

Dixon 3-Way Ball Valves

3-Way Stainless Steel Diverting Ball Valve L-Flow

Features

Features

- Blow-out proof stem

- Adjustable packing gland

- Locking handle

Materials

- Stainless steel ball

- RPTFE seats and stuffing box ring

- Stainless steel handle and nut with vinyl sleeve

Specification

- Rated to 800 PSI (pounds per square inch) CWP (cold working pressure)

- Maximum temperature: 500°F (260°C)

3-Way Bronze Diverting Ball Valve L Flow

Features

Features

- Blow-out proof stem

- Adjustable packing gland

- Can be used with gasoline and diesel fuel

Materials

- Chromium-plated ball

- RPTFE seats and stuffing box ring

- Stainless steel handle and nut with vinyl sleeve

Specifications

- Pressure rating: 400 PSI CWP

- Maximum temperature: 500°F (260°C)

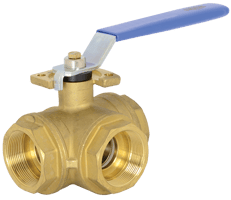

3-Way Brass Diverting Ball Valve T Flow

Features

- Blow-out proof stem

- Adjustable stem packing

Materials

- Chrome plated brass ball

- PTFE seats, seals, and thrust washer

Specifications

- Maximum temperature: 366°F (186°C)

- Pressure rating: 400 PSI WOG (water, oil, gas); 100 PSI saturated steam

High Pressure Full-Bore 3-Way Ball Valve

Feature

Feature

Materials

- Clear zinc carbon steel

- Nickel plated ball

- Nitrile rubber O-rings

Specifications

- Working pressure: 5,145 PSI

- Temperature range: -20°F to 215°F (-28.9°C to 101.6°C)

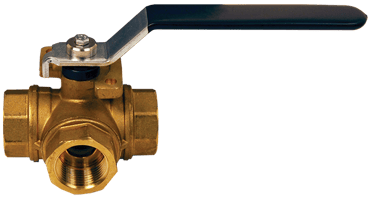

BV3B-Series 3-Way Industrial Brass Ball Valve

Features

- Blow-out proof stem

- Female NPT ends

- Reduced port

- ISO 5211 mounting pad

- L-port and T-port options

Materials

- PTFE seats with O-ring backing

- Chrome plated brass ball

- FKM elastomers

Specifications

- Pressure rating: 400 PSI WOG; 100 PSI WSP (working steam pressure)

- Maximum temperature: 344°F (173°C)

Summary

Multiport ball valves provide an easy solution for applications requiring flow direction control in one valve body. Dixon offers a variety of 3-way valves and actuation capabilities to meet the needs of your application.

For more information, visit dixonvalve.com or call 877.963.4966.