As consumers, we make conscious efforts every day to maintain food safety. We wash fruits and vegetables before consuming, keep milk refrigerated, ice cream frozen, and always cook meat to the proper internal temperature. But have you ever considered what steps manufacturers and processors in the food, beverage, and pharmaceutical industries take to ensure their products and equipment are safe for production?

One method of prioritizing food safety in the design and fabrication of food processing equipment is through 3-A certification.

What is 3-A certification?

In the 1920s, the first hygienic standards for dairy processing equipment were created. They became known as 3-A standards because three groups collaborated to improve the design and sanitation of equipment: manufacturers, processors, and regulatory sanitarians.

Today, 3-A certifications are managed by 3-A Sanitary Standards, Inc. (3-A SSI), a non-profit organization representing equipment manufacturers and processors. More than 100 years later, 3-A standards have expanded to include hygienic standards and accepted practices for not only dairy processing, but also other food, beverage, and pharmaceutical processing equipment and systems.

The goal of 3-A certification is to protect consumers from potential contamination by making sure all parts of sanitary equipment are properly cleaned and sanitized. While 3-A SSI does not provide details on how to make a piece of equipment, the organization does provide guidelines on unsanitary elements to avoid during the design and fabrication process of any equipment that comes into contact with consumable products.

What is the 3-A certification process?

In order to obtain 3-A certification for a product used in the food, beverage, or pharmaceutical industry, there are five steps manufacturers must follow.

Step 1: Find the 3-A standard

The first step is to determine if there is a 3-A standard for the product. According to 3-A SSI, there are currently 70 sanitary standards in these general categories:

- Vessels

- Fillers

- Valves and Fittings

- Pumps and Mixers

- Heat Exchangers

- Conveyors and Feeders

- Instruments

- Farm/Raw Milk

- Cheese and Butter Equipment

Step 2: Purchase the standard

Manufacturers are responsible for purchasing and maintaining a copy of the most up-to-date standard for their chosen product. The standards are listed and available for purchase on the 3-A SSI website.

Step 3: Test the product

Upon reviewing the specific 3-A standard, the product must be tested to ensure it meets the hygienic guidelines. Manufacturers are responsible for demonstrating and documenting the effectiveness of the product’s Clean-In-Place (CIP) system. Testing methods vary depending on the product, but the ultimate goal is to ensure all contact surfaces can be adequately cleaned.

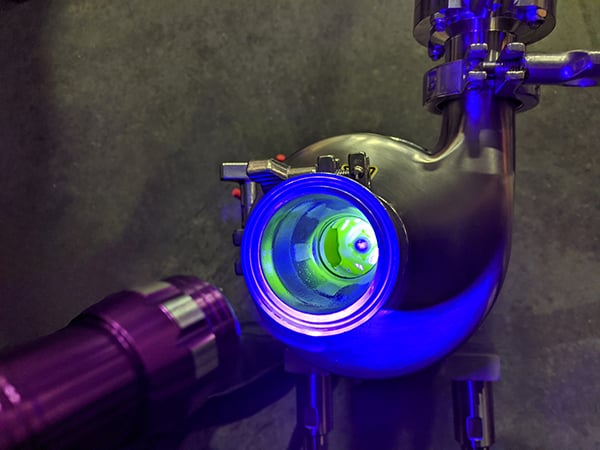

For products like Dixon’s sanitary pumps, Riboflavin is used in the testing process. Also known as Vitamin B2, Riboflavin is fluorescent under UV light and is water soluble. To conduct the test, Riboflavin tablets are dissolved in water. The solution is cycled through the pump system for 15 minutes to coat the contact surfaces. A UV black light is used to ensure Riboflavin residues are visible in the seal. This simulates the residues left behind from the products used with the pumps.

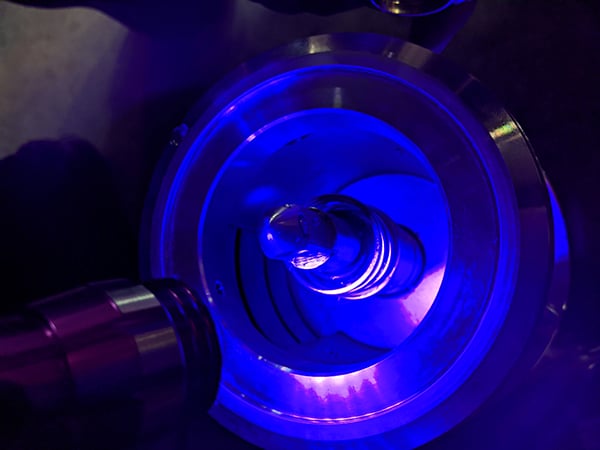

Then, fresh water is used to run a rinse cycle for 3 minutes at a minimum velocity of 5 feet per second, which is the recommended flow rate and pressure. The freshwater rinse cycle is repeated two more times. After draining, the pump is inspected again using the UV black light. This time, the pump casing is disassembled to conduct a thorough inspection. The back plate, impeller, stub shaft, and the dead ends under the seal and O-rings are all observed.

If the CIP was successful, 100% of the Riboflavin residue should be removed from all surfaces. If the test fails, manufacturers must document where the Riboflavin was detected. The product should be reevaluated, and modifications made to the pump seal and/or CIP parameters. The test is repeated until the product passes. 3-A certification cannot be obtained until a passing result is achieved.

Step 4: Complete a third-party verification (TPV)

Once a product has successfully completed the testing process, a 3-A SSI Certified Conformance Evaluator (CCE) conducts a TPV. The CCE goes to the facility that produces the final assembly of the equipment, reviews the test results, and ensures the product meets all of the requirements for the specific 3-A standard.

Step 5: Get a 3-A certificate

When the CCE signs off on the TPV, a product can officially be 3-A certified. A certificate is issued to the manufacturer and is valid through December 31 of the current year. As long as there are no significant changes to the product, and the standard has not been updated, the 3-A certification can be renewed annually. A TPV inspection is required every five years.

How do you know if a product is 3-A certified?

Equipment that has successfully completed the certification process will display the 3-A symbol, which is a registered trademark of 3-A SSI. Only products that have successfully met the requirements and obtained a 3-A certificate are legally eligible to display the symbol and be marketed as 3-A certified.

In addition, manufacturers can provide a copy of the official 3-A certification for their products. Dixon’s 3-A certifications are available on the website.

Benefits of 3-A certification

Although 3-A certification is not mandatory, it is beneficial to manufacturers, processors, and consumers alike. Manufacturers and processors benefit from 3-A certification because it promotes acceptance by the U.S. Department of Agriculture (USDA), Food and Drug Administration (FDA), and state regulatory authorities. In addition, 3-A certification verifies all product contact surfaces can be mechanically cleaned or easily dismantled for cleaning and/or inspection. This saves time and money.

Consumers benefit from 3-A certification because the sanitary standards ensure equipment can be properly cleaned to reduce the risk of contamination or foodborne illnesses.

Summary

Equipment manufacturers and food, beverage, and pharmaceutical processors play a vital role in ensuring the health and safety of consumers. Products and equipment used to make or process products for human consumption must be cleaned properly and effectively to prevent contamination. 3-A certification helps meet this goal by providing a set of sanitary standards to follow, and a stringent testing system to demonstrate the adequate performance of CIP systems.

Dixon is proud to offer a variety of 3-A certified products. For more information on the products we offer that hold 3-A certification, visit dixonvalve.com.