Safety and environmental stewardship are essential in industrial settings, yet many industries grapple with a largely invisible problem that poses serious risks to both human health and the environment: fugitive emissions.

Fugitive Emissions Overview

Fugitive emissions are the unintentional release of gases or vapors from pressurized equipment due to faulty seals, connections, or other mechanical failures. These emissions can escape from various industrial sources such as valves, pumps, flanges, and other components in chemical processing plants, oil refineries, and manufacturing facilities. The leaks often go unnoticed due to their diffuse nature and are a significant contributor to environmental pollution. Fugitive emissions differ from exhausts or emissions deliberately vented from a process, making them difficult to quantify and monitor. Key chemicals associated with fugitive emissions include volatile organic compounds (VOCs), greenhouse gases (GHGs), and hazardous air pollutants (HAPs).

VOCs are organic chemicals that evaporate easily at room temperature, contributing to air pollution. A common example is benzene, a compound used in the production of plastics, resins, and synthetic fibers. When VOCs leak into the atmosphere, they can form ground-level ozone, a major component of smog, which negatively impacts air quality and human health.

GHGs, such as carbon dioxide and methane, are critical drivers of climate change. Even small amounts of methane can have a significant impact on global warming due its potency as a GHG.

HAPs are toxic chemicals that pose a threat to human health and the environment, even at low levels. A notable example is formaldehyde, which is used in various industrial processes, including the production of building materials and household products. Fugitive emissions of HAPs can cause long-term health problems, including cancer, reproductive issues, and damage to the nervous system.

Fugitive Emissions Impacts

Although the leaks are small, across a large facility the amount of lost product adds up to a very large volume, especially for constant, around-the-clock operations. The emissions are a significant contributor to air pollution and have profound safety, environmental, and economic consequences. The release of fugitive emissions poses several safety hazards. The types of risks vary depending on the nature of the substances involved, but common dangers include toxicity, flammability, and corrosiveness.

Some fugitive emissions consist of hazardous chemicals that can cause health problems upon inhalation or skin contact. Other gases are highly flammable; even small leaks can result in explosions, especially in confined spaces or in areas where other ignition sources are present. Benzene leaks are a prime example of both toxicity and flammability concerns. Additionally, acids and other caustic substances can corrode metal surfaces to eventually cause equipment failures leading to larger leaks, malfunctions, or safety hazards.

Beyond immediate safety hazards, fugitive emissions have broader environmental implications. Given the significant environmental impact, governments around the world have enacted strict regulations to limit and reduce the occurrence of fugitive emissions. Violating these regulations is not only detrimental to the environment but can also lead to monetary damages.

The Cost of Fugitive Emissions

In the U.S., the EPA uses consent decrees as a penalty to cease or correct certain actions or processes that are polluting the environment. Many major refineries and chemical plants operate under consent decrees that require the installation of equipment that will help reduce fugitive emissions. The consent decrees include payments of penalties, which have been as much as $40 million in the past.

Regulatory compliance is also driving industries to adopt more effective leak detection and repair programs. These programs involve regular monitoring of equipment and facilities to help identify and quantify fugitive emissions. This allows facilities to address leaks before they cause significant environmental harm or lead to costly fines.

The cost of environmental compliance is just one component of the economic consequences of fugitive emissions. Operating costs should be considered, as well. Making steam requires energy, which comes at a price. A boiler fired with natural gas producing 450 PSI saturated steam and supplied with 230°F feedwater will yield a steam cost of $2.89 per 1,000 lb. A small valve leak can be estimated by comparing it to leakage through an orifice. A 1/32” orifice at 450 PSIG will yield a flow of about 10 lbs per hour. Even with these conservative estimates, the cost of the leakage comes to $253.16 per valve, per year. The EPA estimates that there are an average of 7,400 valves at a typical refinery or chemical plant, which means reducing leakage can have a significant impact. A leak-free steam valve not only saves product to benefit the bottom line but also pays for itself in terms of energy savings in a short amount of time.

According to the EPA, 62% of total uncontrolled VOC emissions at a typical facility come from valves. These numbers are not trivial; any effort to reduce emissions from valves goes a long way. One of the challenges in reducing fugitive emissions is that industrial valves operate under dynamic conditions. The valves are subjected to wear and tear over time, making it difficult to maintain a long-term seal without leaks. However, there is a robust, reliable solution to the challenges posed by fugitive emissions—bellows sealed valves.

Bellows Sealed Valves and Fugitive Emissions

Bellows sealed valves are designed to address the limitation of conventional valve designs, particularly in high-risk applications where fugitive emissions must be minimized. The bellows seal expands and contracts like an accordion as the valve stem moves up or down, enabling precise control of the valve while maintaining a tight, leak-proof seal. Unlike conventional valves that rely on gland packing to seal the stem and bonnet, bellows sealed valves use welded connections. The bellows is welded to both the stem and the valve body, creating a seamless barrier that prevents leaks, even in high-pressure or corrosive environments. Since bellows sealed valves rely on something other than packing material that degrades over time, they require less frequent maintenance and repair. Spending less time on maintenance means having more time to make products, which ultimately has a positive impact on uptime and operational costs.

One major problem with traditional packed valves is their tendency to loosen up in applications with a lot of thermal cycling. Opening and closing the valve causes rapid wear on the packing and leads to leakage of hot transfer fluids or steam. In contrast, bellows sealed valves require no adjustment, are durable, and can withstand extreme, corrosive environments, providing a longer service life. Installing bellows sealed valves in the hottest section of the thermal loop eliminates the chance that a leak will cause a serious safety hazard.

There are two ways to manufacture bellows: hydroforming or edge welding. Hydroforming involves pressurizing a metal tube into metal folds, while edge welding essentially welds a series of washer-like plates to form the accordion shape. Both methods form a bellows seal that completes the same task. However, hydroformed bellows are typically larger and take up more space than welded bellows. There is also the perception that hydroformed bellows are stronger and will last longer because they incorporate fewer welds, but as long as edge-welded bellows are designed and fabricated correctly, and qualified to the MSS SP-117 standard, the service life should be the same.

When specifying a bellows sealed valve for a particular application, it is imperative to consider media/corrosion resistance, temperature rating, pressure rating, and cycle life. Standards such as ISO 15848-1, ISO 15848-2, API 622, API 624, and API 641 should be consulted during the selection process. These specifications ensure bellows sealed valves are tested rigorously for performance under challenging conditions, significantly reducing the likelihood of leaks.

It is important to note that there are low emissions valves designed to minimize fugitive emissions. While these valves may meet regulatory standards or EPA requirements for emissions control, they depend on correct installation, can require adjustment, may have a shorter lifespan, and do not completely eliminate leaks. Therefore, in a critical application requiring absolute sealing, a bellows sealed valve with zero emissions is ideal.

Bellows Sealed Valve Applications

When it comes to reducing fugitive emissions, bellows sealed valves are advantageous for a variety of applications. In refineries, where hydrocarbons and hazardous chemicals are processed, bellows sealed valves are used in steam, heating fluid lines, and volatile chemical services to prevent leaks. These valves are essential for ensuring emissions are contained. In the pharmaceutical and chemical industries, purity and safety are critical. Bellows sealed valves are used to prevent the contamination of products by atmospheric gases or the release of toxic fumes. Bellows sealed valves are also utilized in nuclear and thermal power plants to prevent the leakage of radioactive gases or steam. Cryogenic applications also benefit from the use of bellows sealed valves where gases such as nitrogen, oxygen, and argon must be stored and transported at extremely low temperatures. These valves ensure there are no leaks, even under extreme temperature fluctuations.

Dixon Bellows Sealed Valves

Dixon Eagle brand of bellows sealed valves have a long history of reliability in steam, heat transfer oil, and toxic inhalation hazard applications, making our technology an excellent choice when looking to reduce fugitive emissions.

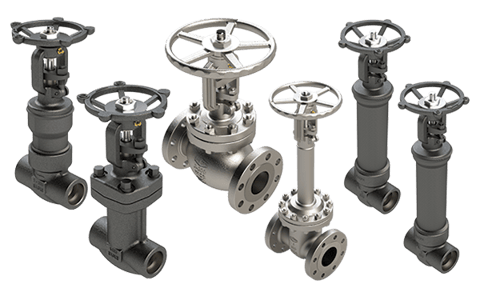

Forged Bellows Sealed Valves: F8-Series Globe, G8-Series Globe, H8-Series Gate, W8-Series Gate

.png?width=600&height=283&name=Forged%20Bellows%20Sealed%20Valves%20(F8%2c%20G8%2c%20H8%2c%20W8).png)

Sizes

- 1/2”, 3/4”, 1”, 1-1/2”, and 2”

Features

- Welded or bolted bonnet

- Classes: 150, 300, 600, and 800

Materials

- Body and bonnet: forged A105N or F316L

- Bellows: 321 stainless steel or Inconel 625

- MTRs available

Specifications

- End configurations: socket weld, threaded, or flanged

- Basic design: API 602

- End flange: ASME B16.5

- Threaded ends: ASME B1.20.1

- Face to face: ASME B16.10

- Bellows: MSS SP-117

Bellows Sealed Valves: J-Series Globe and L-Series Gate

Sizes

- 3”, 4”, 6”, and 8”

Features

- Bolted bonnet

- Classes: 150, 300, and 600

Materials

- Body and bonnet: cast A216 WCB

- Gasket: 316 stainless steel and graphite

- Bellows: Inconel 625

- MTRs available

Specifications

- End configuration: raised face (RF) or butt weld (BW) schedule 40

- Basic design: ASME B16.34

- End flange: ASME B16.5

- Butt weld: ASME B16.25

- Face to face: ASME B16.10

- Bellows: MSS SP-117

Summary

Fugitive emissions are a silent but significant threat in industrial operations. Bellows sealed valves offer an effective solution for reducing fugitive emissions, ensuring compliance with environmental regulations, and contributing to a cleaner, safer world. As industries continue to prioritize emission control and sustainability, the demand for bellows sealed valves is expected to grow, cementing their role as a critical component in the fight against fugitive emissions.

For more information, visit dixonvalve.com or call 877.963.4966.

.png?width=343&height=300&name=Bellows%20Sealed%20Valves%20(J-Series%2c%20L-Series).png)