Admit it, at some point in your life you have used a garden hose to spray someone. This means you know that using your finger to cover part of the hose end makes the water spray farther and faster. But what makes this phenomenon occur? It has to do with pressure and force, two important aspects of hose assembly dynamics.

While we obviously don’t recommend spraying someone with a hose in industrial applications, and you shouldn’t let your hand interfere with the media being transferred, understanding the dynamics of a hose assembly is essential for any application.

STAMPED

Whether reviewing hose assembly components on your own or working with a hose professional, it is important to consider the STAMPED acronym. STAMPED stands for size, temperature, application, media, pressure, ends, and Dixon®. The acronym is a vital tool in the proper selection of components to make any assembly. Consistent use of this tool will dramatically reduce the risk of an assembly not performing as intended or even failing in service.

When fabricating and specifying hose assemblies ask the following questions:

Size: What is the inside diameter (I.D.) of the hose? What is the outside diameter (O.D.) of both ends of the hose? What is the overall length of the assembly required?

Temperature: What is the temperature range of the media (product) that is flowing through the hose assembly? What is the temperature range of the environment that surrounds the outside of the hose assembly?

Application: How is the hose assembly actually being used? Is it a pressure application? Is it a vacuum (suction) application? Is it a gravity flow application? Are there any special requirements that the hose assembly is expected to perform? Is the hose being used in a horizontal or vertical position? Are there any pulsations or vibrations acting on the hose assembly?

Media: What media/material is flowing through the hose assembly? Being specific is critical. It is important to check for abrasive materials, chemical compatibility, etc.

Pressure: What is the maximum pressure, including surges or spikes, that the hose assembly will be subjected to? Always rate the maximum working pressure of your hose assembly by the lowest rated component in the system.

Ends: What couplings have been requested by the user? Are they the proper fittings for the application and hose selected?

Dixon: Based on the hose, fittings, and attachment method used, Dixon recommends all assemblies be permanently marked with the designed working pressure and intended media. Do not use fittings or ferrules from another manufacturer with Dixon products due to the differences in dimensions and tolerances. We also recommend that all hose assemblies be tested frequently.

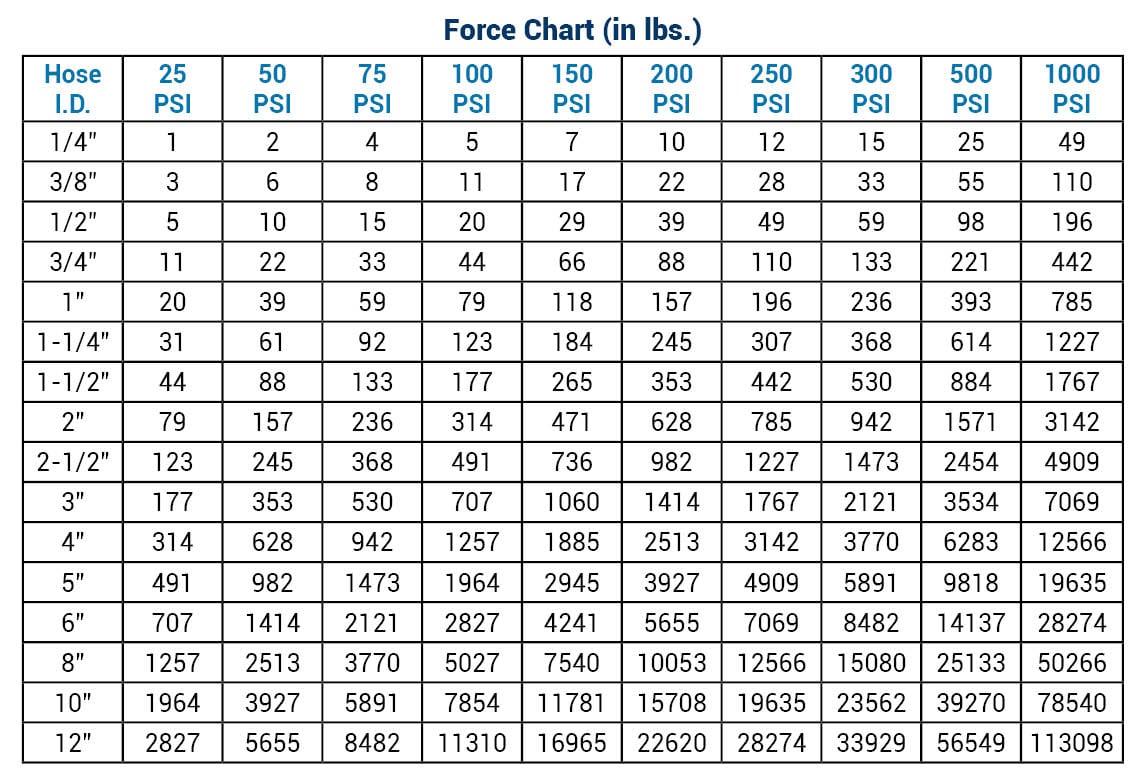

Force Chart

There are two energy dynamics present in every assembly: pounds per square inch (PSI) and force. PSI, also known as Pascal's Law, is equal pressure in all directions. Force is the linear energy that runs the length of the assembly directly affecting the holding power of the couplings. Force, which is calculated by multiplying the area of the I.D. by the working pressure, is a major factor in selecting coupling and clamping devices to work with a particular size/pressure combination.

In the garden hose example mentioned earlier, putting a finger over part of the end of the hose changes the area available for water to leave the hose. The same amount of water moves through the hose, but more has to come out at a time to accommodate the change in area. Thus, because of the relationship between area, pressure, and force, when the area (hose I.D.) decreases, the pressure increases.

Did you know the couplings of an 8” assembly at 100 PSI must withstand the weight of a full-size pickup truck (Ford 150, Chevy Silverado, Ram 1500) hanging from it? They do! Or did you know that a 4” industrial hose at 150 PSI has over three times the stored energy of a 1/2” hydraulic hose at 3000 PSI. See the chart below for more information.

Note: For hose I.D.’s from 1-1/4” to 12” the force in pounds is greater than the PSI.

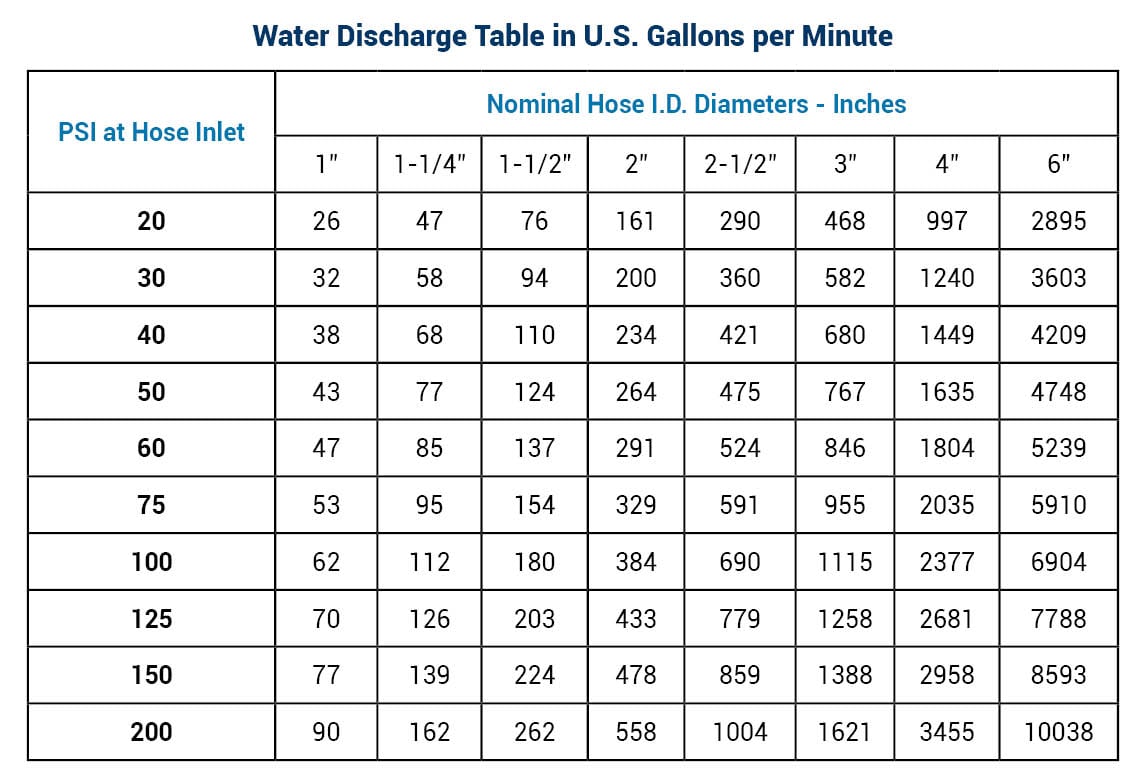

Water Discharge Table

Have you ever wondered just how much material is moving through a hose assembly? A 3” hose at 100 PSI, if accidentally disconnected or fails, can put almost 300 gallons of whatever the media is in an undesirable location in just 15 seconds! A 6” assembly at 150 PSI can fill the average home swimming pool, which is approximately 20,000 gallons, in a little over two minutes.

The chart below indicates the flow of water in gallons per minute through 100-foot lengths of straight, smooth-bore hose.

The figures in the table are meant to be used as a guide since the hose inside diameter tolerance, the type of fittings used, and orifice restriction all influence the actual discharge. Thus, variations plus or minus from the table may be obtained in actual service.

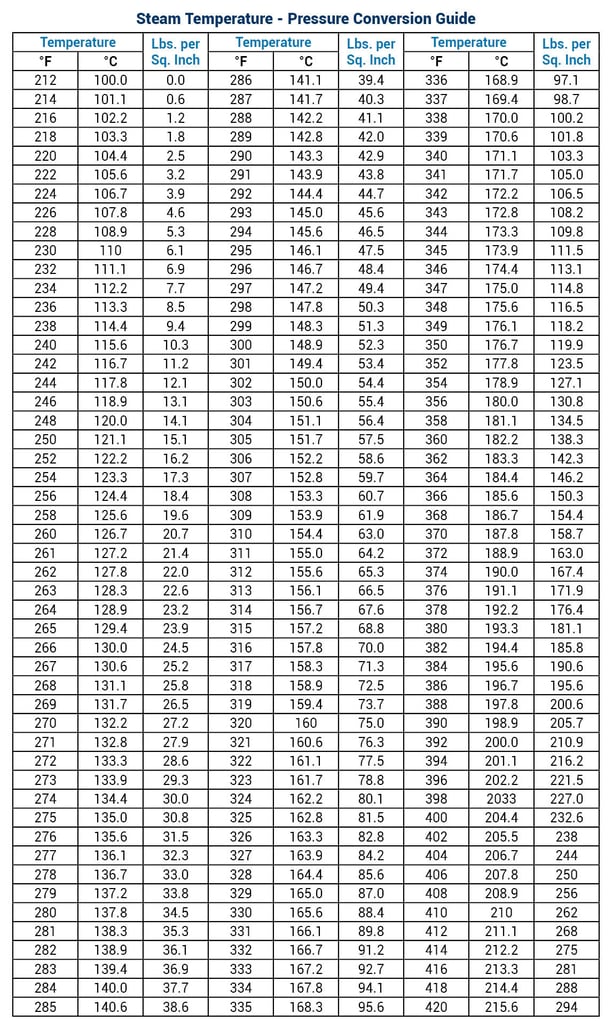

Steam Temperature

Steam is one of the most dangerous products an employee of any plant has to deal with. In fact, steam hoses have a 10:1 safety factor, compared to other media which have a 3:1 or 4:1 safety factor. Steam is a compressible product that can, when suddenly released, explode violently. It is also very hot. Steam at 250 PSI is 406°F (207°C). Even low pressure steam can be very dangerous. Steam at 30 PSI is 274°F (134°C). The hose and coupling options for steam service are limited. Dixon offers Crimp Boss® steam fittings, Boss® ground joints, and Boss® clamps which are all suitable for steam service. Before making any decisions on steam assemblies, talk to a hose professional.

Summary

Understanding the dynamics of a hose assembly is imperative for a successful operation. Using the STAMPED acronym to guide the decision-making process can help ensure the proper hose and fittings are selected for a specific application. In addition, having a working knowledge of force, pressure, water discharge, and steam can help prevent accidents and promote safety.

For more information, visit dixonvalve.com or call 877.963.4966.