According to a survey conducted in 2023, 65% of U.S. consumers want to purchase products that are made in America. This is great news for companies like Dixon, where we pride ourselves on being a North American manufacturer for more than 100 years.

History of Dixon

Dixon was established in Philadelphia, Pennsylvania, in 1916 by Howard W. Goodall. A year later the rotary hose coupling was patented. The rotary hose coupling, a high-pressure fitting used in oil drilling, became the largest-selling item in the Dixon product line for the next 15 years.

In 1934, Dixon’s reach expanded to include manufacturing locations in Canada, transitioning the company from just a U.S. manufacturer to a North American manufacturer.

A few years later in 1939, World War II started, but Dixon continued manufacturing products. Many Dixon products fell under the federal government priority system and were used by industry and the military in the war effort. Dixon manufacturing facilities were used almost entirely for military contracts. The largest of which was to produce 380,000 fuse plugs for anti-aircraft shells, which were run on a brand new six-spindle screw machine, the only one in the Philadelphia area at the time.

In 1976, Dixon relocated to Chestertown, Maryland, and continued to proudly manufacture products in North America. Today, Dixon serves a variety of markets including agriculture and forestry, chemical processing, construction, energy/oil and gas, fire protection, food and beverage, maintenance repair operations, mining, steel processing, and transportation. Genuine Dixon products are still manufactured in North America using the highest quality standards and have become a part of our legacy. How we advertise our products may have changed over the years, but one thing has remained consistent. With almost 110 years in business, our commitment to providing The Right Connection® remains steadfast.

Legacy Products

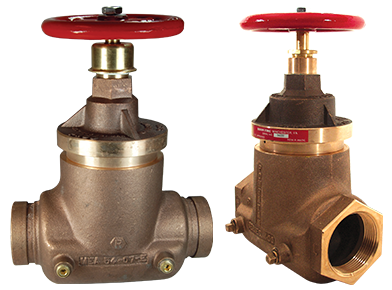

We are proud of all the hose couplings, valves, dry disconnects, and other fluid and transfer and control products we manufacture and supply. However, there are a few that stand out as integral aspects of our business.

Air King®

Dixon Air King couplings are recommended for use on air lines for virtually any type of pneumatic equipment. The maximum recommended working pressure for Dixon Air King universal couplings is 150 PSI or less at an ambient temperature of 70°F (21°C).

Dixon Air King fittings have a universal head that is identical for all parts (hose ends, male NPT, and female NPT) within the 1/4” to 1” range. This enables any two fittings (within that range) to be directly connected regardless of hose shanks or threaded size. The ferrules can be swaged or crimped depending on your coupling installation requirement.

Cam & Groove

In 1980, Dixon entered the cam & groove market by applying for a patent for Boss-Lock, a cam & groove fitting with a safety locking handle. Since then we have developed an extensive offering of cam & groove couplings and accessories. For a comparison of Dixon’s cam & groove offering, check out this blog post.

Boss® Ground Joints

Boss ground joints supply a convenient threaded fitting to connect two lengths of hose, or a single length to a male or female threaded outlet. They are designed for use with Boss clamps or crimp ferrules for non-steam applications.

The stem is clamped to the hose in one-half of the Boss ground joint connection. The Boss ground joint spud of the coupling serves as the other half and is usually fixed to the equipment. The two halves are connected or disconnected by rotating the wing nut on to the spud. When connected they achieve both a mechanical and a pressure seal. A seal forms when the metal head of the stem makes contact with the patented polymer seat in the Boss ground joint spud. Boss ground joints are recommended for air, water, fluid petroleum, chemical, and steam service up to 450°F (232°C).

GSM Armored Hose

Dixon began manufacturing GSM armored hose as a solution for steel mills in 1964. GSM armored hose is available in 1/4”-12” I.D. The flexible armor protects from heat, slag splash, and harsh environments found in steel mills and is heat resistant up to 1000°F (537°C).

King Combination Nipples

King combination nipples are recommended for low-pressure discharge and suction service for compatible liquids. They are available in a wide variety of materials and styles. The NPT thread end combination nipples have a knurled wrench grip to enhance tightening and loosening.

Swivel Joints

Dixon entered the industrial swivel market in 1985 and has continued to expand our swivel product line today. Swivel joints are used in pipelines or in combination with hoses to eliminate hose twisting. The maximum recommended working pressure for Dixon swivel joints at an ambient temperature of 70°F (21°C) for 1”-24” sizes ranges from 150 PSI to 1000 PSI depending on the material.

Dixon entered the industrial swivel market in 1985 and has continued to expand our swivel product line today. Swivel joints are used in pipelines or in combination with hoses to eliminate hose twisting. The maximum recommended working pressure for Dixon swivel joints at an ambient temperature of 70°F (21°C) for 1”-24” sizes ranges from 150 PSI to 1000 PSI depending on the material.

Summary

With legacy products and so much more, Dixon has brought value to the community and served multiple markets for many years. We are a proud North American manufacturer with production facilities in Illinois, Maryland, North Carolina, Ohio, Texas, and Virginia as well as Canada.

Dixon is committed to producing high-quality products built to last. Our strategic objective is to create solutions that make products safe, leak-free, longer-lasting, and readily available. For more information, visit dixonvalve.com or call 877.963.4966.